The relatively young Prognosis team has just been established for four years. Currently, there are ten members on board, most of them R&D engineers who have accumulated years of experience in world-renowned industrial computer companies in the past. At the beginning of its business, the company identified the specific field of vibration sensing technology, aiming to combine smart analysis with accurate vibration sensing technology and render a high-performance "Prognostic and Health Management (PHM)" system, which is one of the most difficult areas in industrial automation. This smart system can help companies foresee and thereby prevent problems. For example, companies will be able to predict abnormal conditions and wearing conditions of equipment, prevent production loss, and also save on equipment energy consumption.

The team added that, just five or six years ago, the development conditions and popularity of AIoT were not yet mature. However, under the impact of the pandemic, both traditional industries and high-tech electronics or semiconductor factories experienced increasingly great demand for unmanned operation with higher degrees of safety, so various industries have accelerated the introduction of AIoT technology, and the demand for equipment failure prognosis has also increased significantly. Such demand led to an over ten-fold increase in the business of Prognosis Technology, reassuring the team that they have chosen the right track.

Even though the IoT market has a large appetite, such demand can be further categorized under various areas. For instance, the demand side involves equipment control, production line scheduling, yield and utilization rate control; the supply side deals with a variety of product equipment, software/hardware combinations, etc. From a simple sensor to an entire factory building, so many things can fall within the scope of IoT production. In other words, the goal falls within the category of environmental protection, or energy management to be more precise.

To this, General Manager of Prognosis Technology Arthur Lu explained, "Vibration is an important early indicator for equipment diagnosis, which can indicate whether the equipment is wearing, or when it can no longer meet the requirements of energy saving and production quality." Using the human body as an analogy, when someone is infected with Covid-19, they will start to have a fever, but the body has been infected by the virus for a period of time. Some people can even be asymptomatic, so we can say that fever is a lagging indicator in this regard. Now, when it comes to a machine, when the sensor detects abnormal current or high temperature during operation, the problem may have existed for a period of time. Instead, if we analyze the frequency and state of vibration, we can better detect whether abnormality exists in the machine at an early stage. This is the concept of preventive diagnosis for equipment.

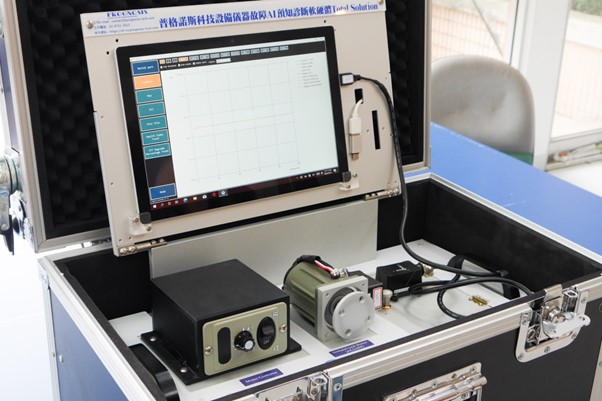

Compared with other major manufacturers who mostly use analog signal sensing technology, the vibration sensor made by Prognosis is literally a next-generation sensor. In addition to the function upgrade (able to process digital signals), the sensor can directly output key characteristic values in the time domain and frequency domain spectrum from the sensor, or even the device abnormality diagnosis results implemented by the AI model in the sensor. What is more, the sensor also passed the explosion-proof MEMS certification by the Industrial Technology Research Institute (ITRI). This matters significantly since for some harsh industrial scenarios (e.g., in a petrochemical plant), explosion-proof performance is not only something nice to have, but also a basic and necessary specification.

Traditional vibration sensors are designed based on the piezoelectricity principle, so the output data are analog signals. In contrast, Prognosis adopts a microelectromechanical design, and a built-in CPU makes it possible for the sensor to process digital signals in real time. Speaking of vibration sensors, in the past, it was believed that vibration sensors only need to be installed in the main axis of the machine, but in fact, when the equipment vibrates, the vibration occurs synchronously in all three axes. If three separate sensors are used, however, key values cannot be measured at the same point. Plus, installing an extra axial sensor will increase the implementation cost by NT$5,000-10,000. Thus, for a factory with hundreds or even thousands of machines, the cost will become a serious operational burden if you also count in the additional equipment and software for the back-end integration of data in each axis. Presently, more than 80% of factories still use traditional analog vibration sensors. Compared with single-axis vibration sensors, three-axis vibration sensors showcase obvious advantages, and Prognosis can achieve the same soft- and hardware performances as international manufacturers, but at only 10% of their cost. Such a competitive edge is the best indicator of the company's great market potential.

And these are just technical upgrades at the hardware level.

Prognosis's Industry 4.0 planning is characterized by systematic thinking. They do not focus on a single product function, but provide complete soft- and hardware integration services instead. When such thinking is reflected at the product level, we can see the company providing smarter and more precise choices of data storage and data use, thereby maximizing service effectiveness for all clients. Vibration is different from other targets of sensing technology such as temperature and humidity, which have smaller fluctuation rates. When it comes to vibration, the amount of data is huge (up to thousands of data entries per second), which is quite a burden for storage and computing performances. To this, Lu noted that the team had once worked with a well-known semiconductor factory in Taiwan. To protect data confidentiality, all the data had to be kept in the internal servers. In the end, the huge amount of data occupied the entire storage space of the servers.

In this situation, the advantages of Prognosis products using microelectromechanical design are even more prominent. Since the sensor has a built-in chip, it can directly perform edge computing when processing data. The data model obtained by AI analysis of a large amount of data is placed inside the computing chip, and the sensor can capture abnormal values in real time and record them. This eliminates the need to record all of the original raw data. "Smart manufacturing has become an inevitable trend; if you record all the data and process them later, it will be inefficient and less smart," Lu added.

Data and algorithms are the two most critical elements of AI. The Prognosis team makes the most out of every bit of data collected, and can even provide information that can only be displayed by million-dollars-worth spectrum analysis equipment. All the above-mentioned niches have allowed Prognosis to win the favor of famous companies in different industries. At present, it has entered Taiwan's leading industries such as semiconductors, optoelectronics, and petrochemicals. It even successfully became the first local supplier of the Taiwan HSR (High Speed Rail). All these accomplishments are the proof of the team's strong R&D capabilities.

With unique vision, solid hardware development technology, and strategic integration thinking, Prognosis has exhibited steady growth in just four years since its establishment. Currently, it is actively looking for more cooperative manufacturers. After the promotion of its products on the "ideas Hatch" platform, the company received much attention and now enjoys greater popularity. Through the assistance of the IoT Service Hub, it accelerated its expansion to industrial IoT, and has already been contacted by or even signed contracts with a number of manufacturers. In the future, the company's growth and achievements are indeed very promising!

>>Find the product(s) you need on the Hatch Market: https://www.ideas-hatch.com/hatch_market_detail.jsp?id=569