Y-BOX NBIoT 發電機監控裝置

可量產雛型

輔導案例

YACO Y-BOX

Y-BOX為一NBIoT發電機監控裝置,透過將Y-BOX加裝於傳統發電機上,監控發電機上水溫、油壓、油量及過盤車等數據,支援發電機營運業者得遠端得知多台發電機狀態,並設定警報通知條件,以實現發電機例行性/預測性保養與即時性異常維修服務。

團隊

亞國機電有限公司

產品規格

長100 mm / 寬50 mm / 高20mm

軟體規格:Web應用程式

硬體元件:MTK MT2625

軟體規格:Web應用程式

硬體元件:MTK MT2625

輔導流程

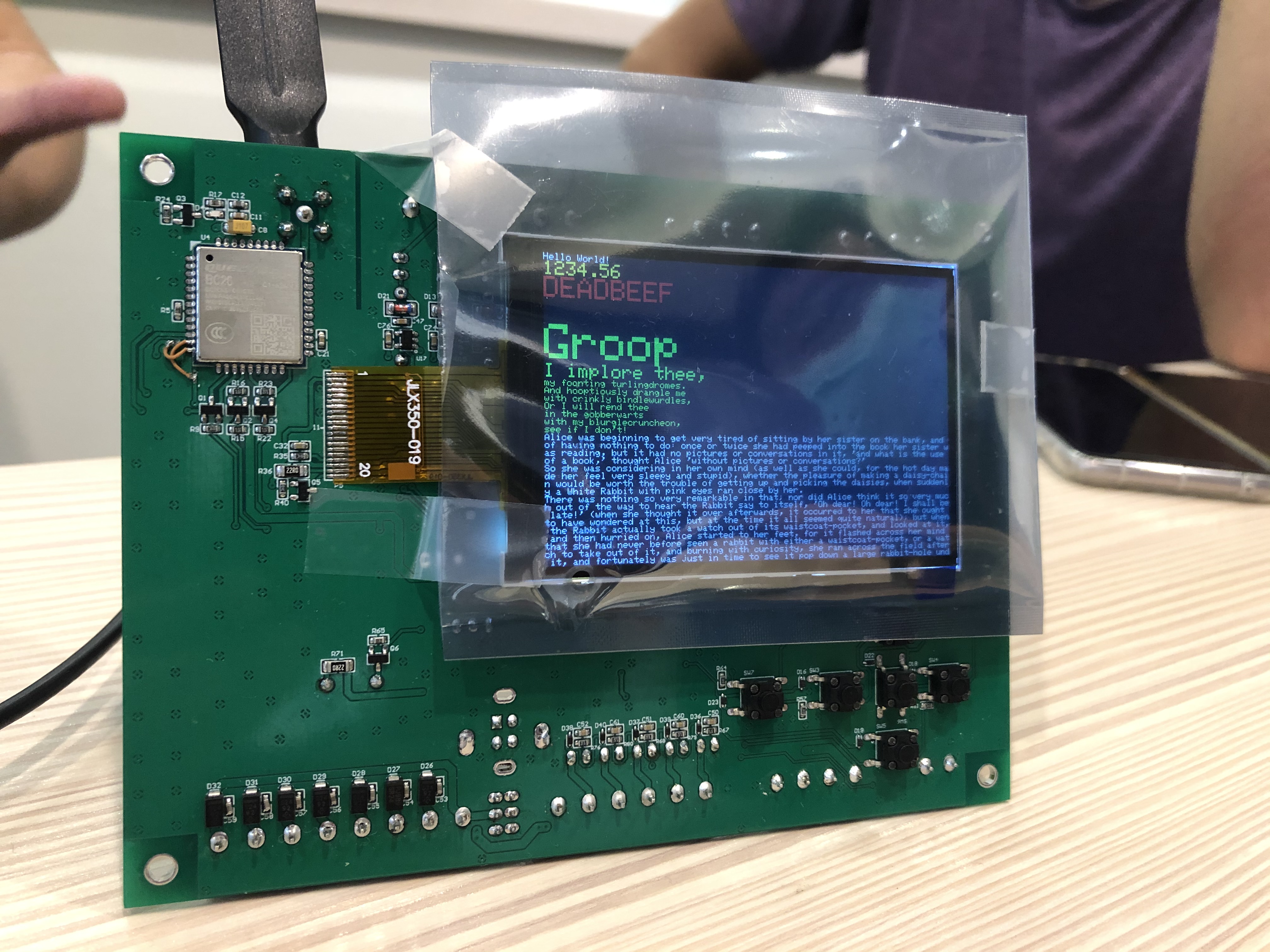

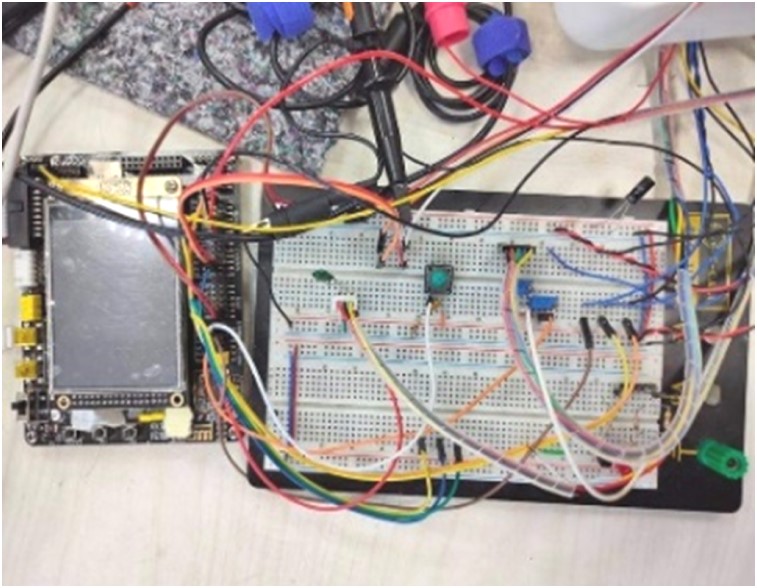

國產方案導入

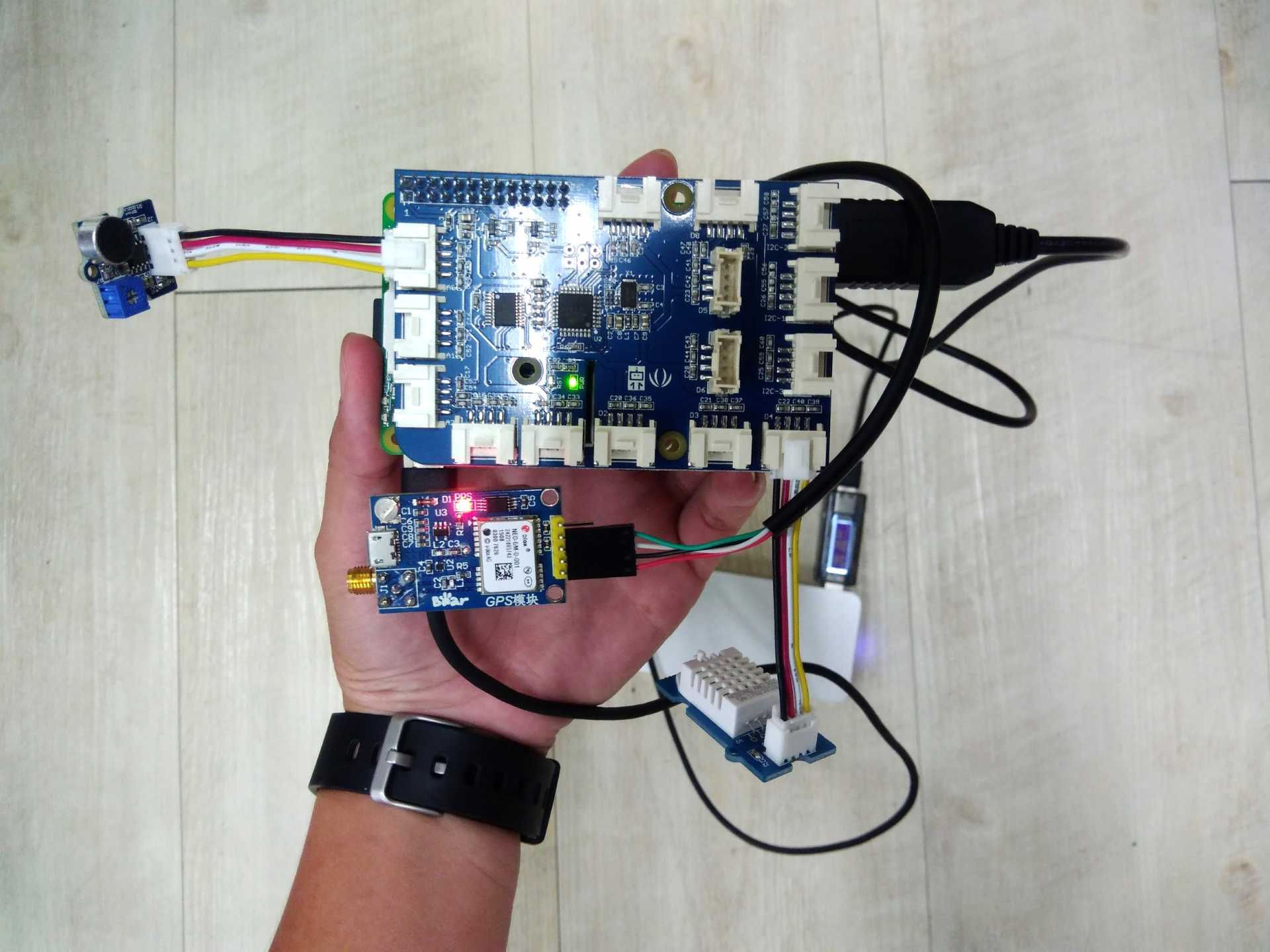

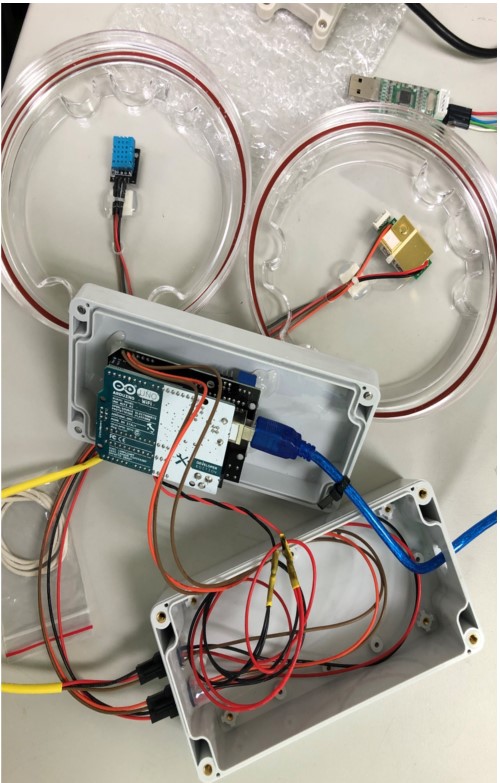

以國產NBIoT開發板DSI2598打造產品雛型,進行產品功能性驗證確認可行性。

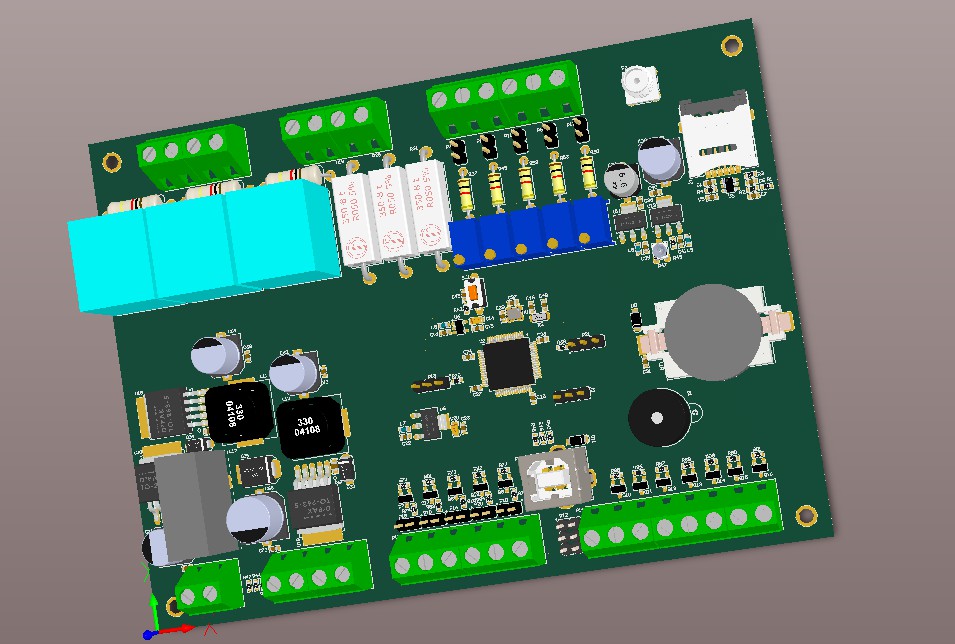

電路整合設計

由服務團有亮科技協助進行電路整合設計,以國產IC MTK MT2625為核心打造NBIoT發電機監控裝置。

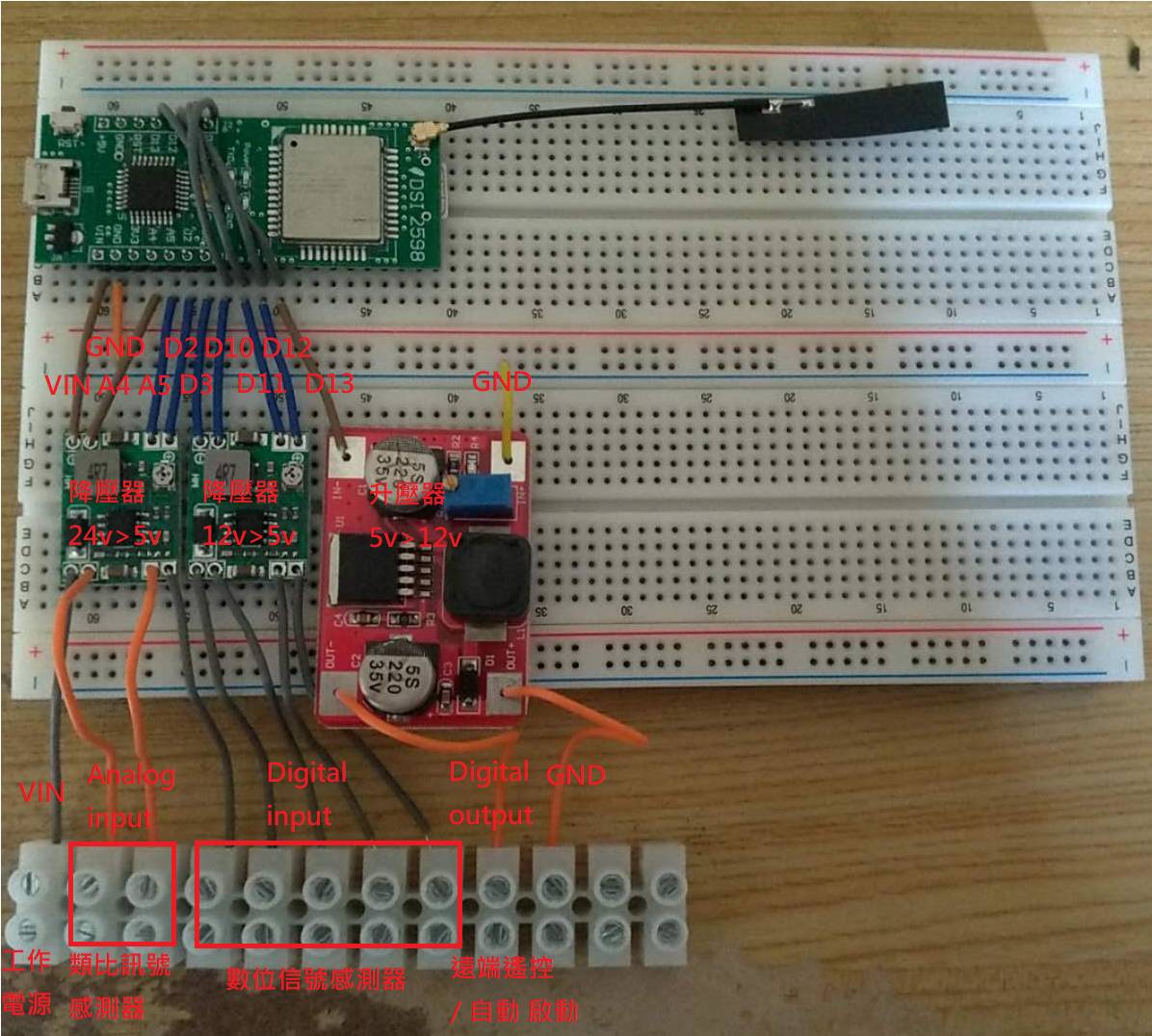

輔導前

利用DSI2598搭配麵包板可動初階雛型

利用DSI2598搭配麵包板可動初階雛型

輔導後

服務團有亮科技協助進行電路整合設計

場域進行實地驗證

電子設計實作並實際利用Wemo車體進行測試

可量產雛型

輔導案例

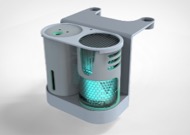

O-Care 共享機車自動消毒劑

針對共享機車安全帽的衛生清潔解決方案,將主體安裝於機車車廂內,此『安全帽清潔機』能解決共享機車的安全帽共用衛生問題,裝置亦提供外部消毒噴口,供使用者進行手部消毒,並配合共享機車現有的雲端解決方案,讓使用者在使用完之後可以確切達到消毒的效果,透過能創造業者其與競爭對手的差異化,提升品牌高度。

團隊

水富士健康科技有限公司

產品規格

尺寸:8cm(長),6cm(寬),10cm(高)

軟體規格:網站、APP

硬體元件:DSI 2598+

軟體規格:網站、APP

硬體元件:DSI 2598+

輔導流程

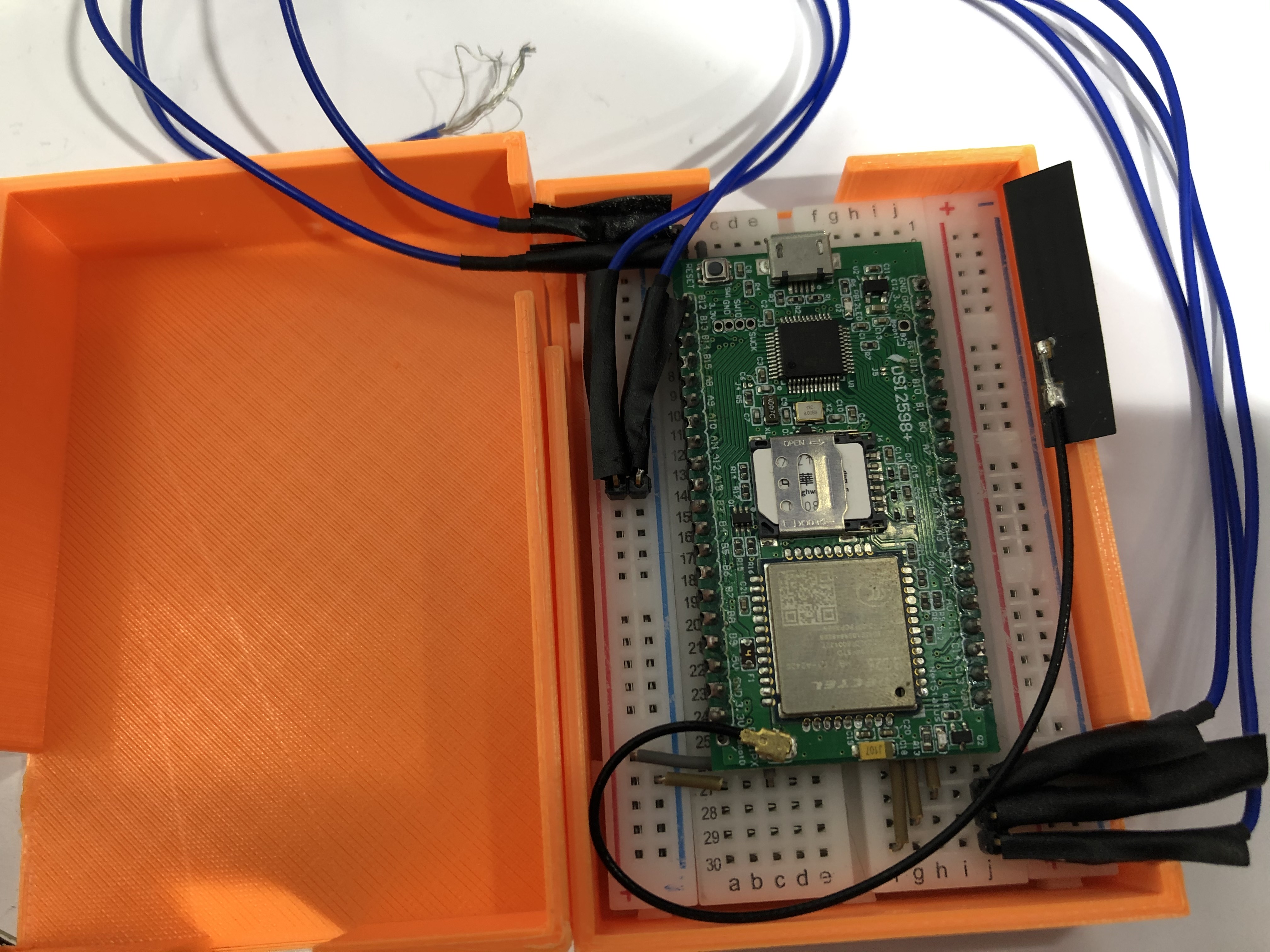

電子電路設計

由服務團祥益企業社系統整合業者協助進行電子電路驗證,採用國產方案DSI2598+並進行相關的POC、EVT、DVT等量產程序,持續朝PVT量產進行中。

共享機車業者媒合與外型設計

媒合共享機車業者Wemo並取得合作備忘錄,由團隊自行進行產品外型設計,安裝於Wemo車上進行實證測試。

輔導前

現有共享機車定期須以人工進行消毒

利用跳線方式進行可行性驗證

輔導後

電子設計實作並實際利用Wemo車體進行測試

電子設計實作並實際利用Wemo車體進行測試

電子設計實作並實際利用Wemo車體進行測試

微型化、搭配機構、軟體整合,準量產DVT雛型

可量產雛型

輔導案例

PD Care家用洗腎遠端管理系統

雅渼醫療是提供家用洗腎管理系統,解決洗腎患者改善在家洗腎溝通成本高、資訊傳達不易及感染延誤治療的痛點。產品包含一個攜帶式腹膜透析機及搭配使用的軟體服務(App/

Web)供患者或醫護端進行資料紀錄及管理。

團隊

雅渼醫療器材股份有限公司(UpperMed)

產品規格

尺寸:長18*寬12*高8(cm)

軟體規格:連接亞馬遜雲的系統平台

硬體元件:ACI810701A-BLE-MD(笙科藍牙模組)

軟體規格:連接亞馬遜雲的系統平台

硬體元件:ACI810701A-BLE-MD(笙科藍牙模組)

輔導流程

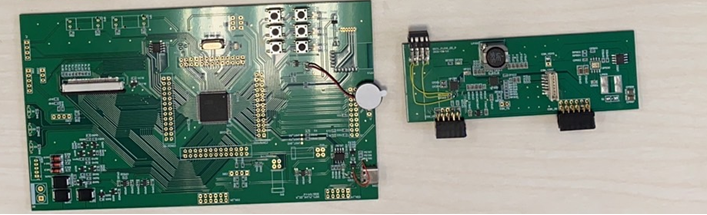

電子電路設計

由服務團展翊豐科技協助進行電子電路設計與驗證,並進行相關的POC、EVT、DVT等量產程序,持續朝PVT量產進行中。

機構外型設計

由服務團磊鑫科技設計協助進行產品機構與外型設計,並配合電子電路整合,進行機構細部微調與打樣。

軟體雲端架構規劃及平台設計 (需要符合HIPAA)

由服務團谷宇科技協助進行流程設計,以符合HIPAA的五大規範。

輔導前

可動初階雛型

輔導後

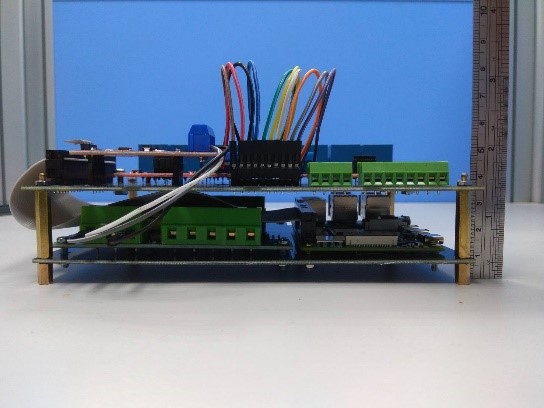

EVT電路板產出

硬體光學搭配韌體測試

智造顧問服務輔導後產品雛型

可量產雛型

輔導案例

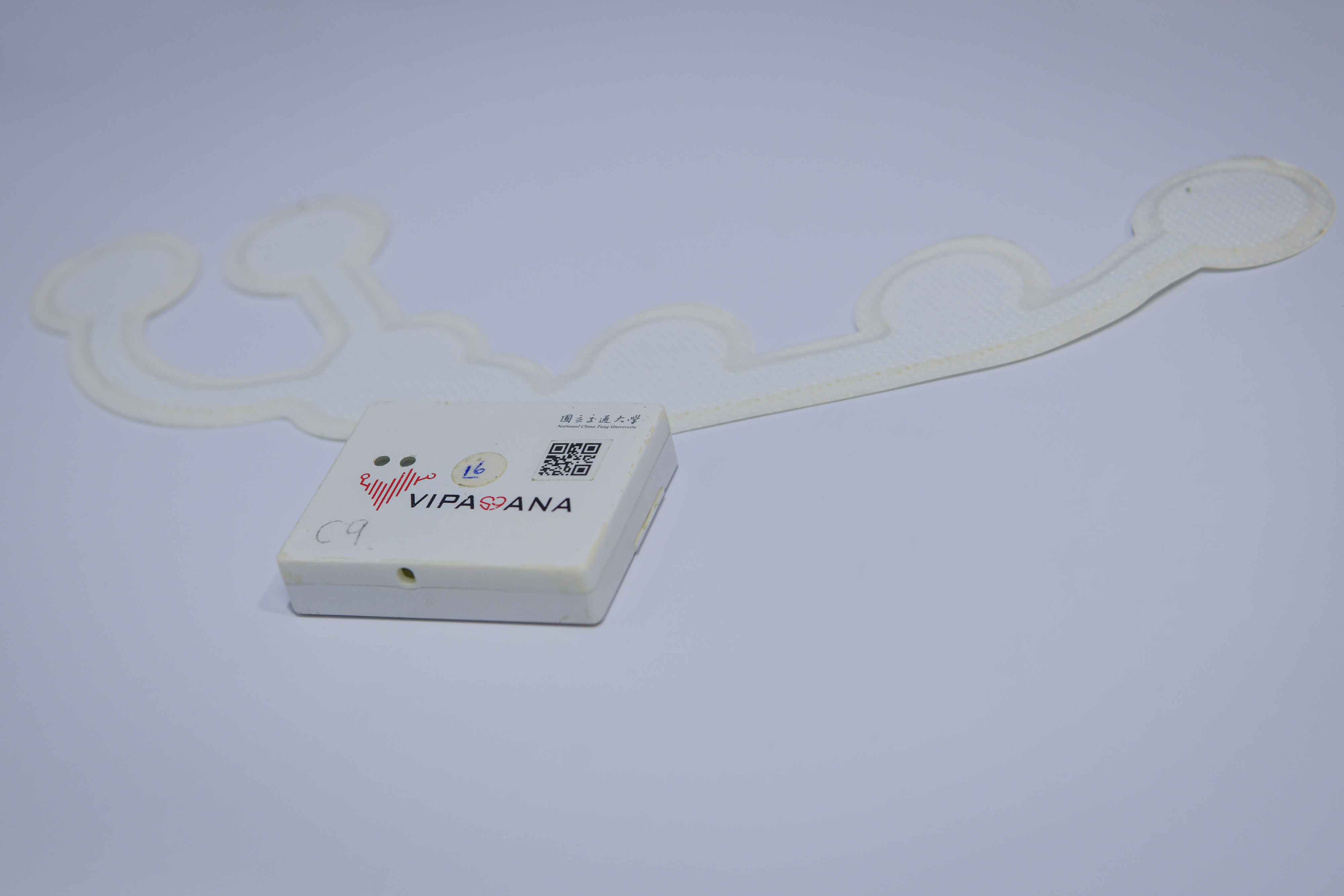

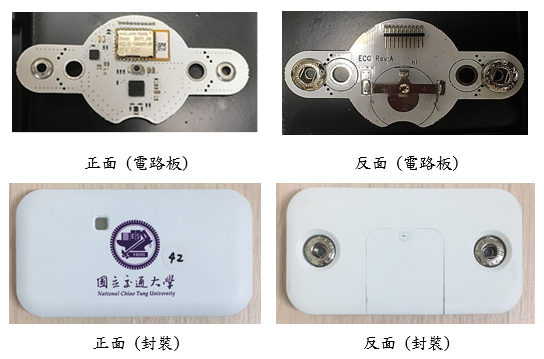

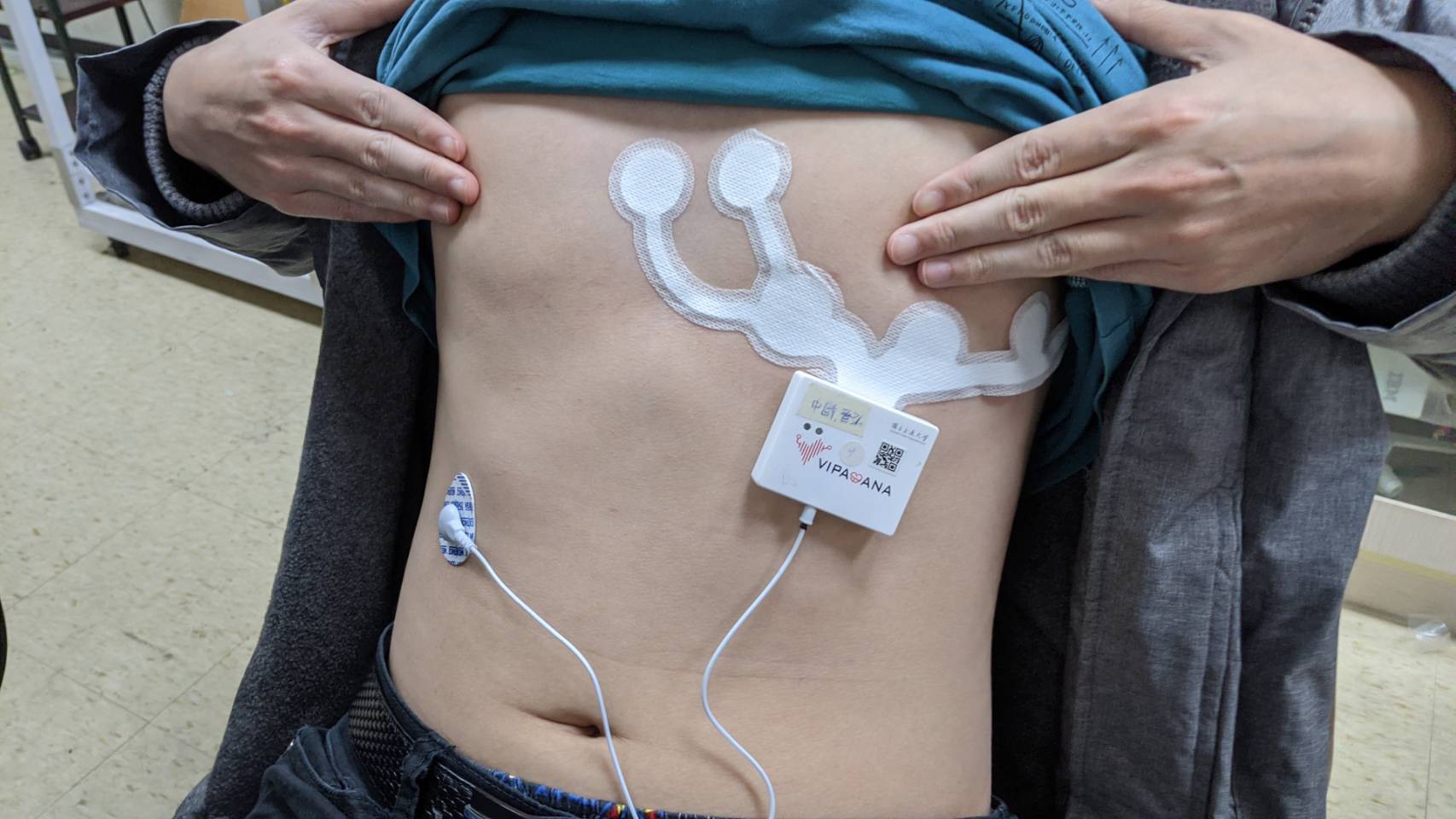

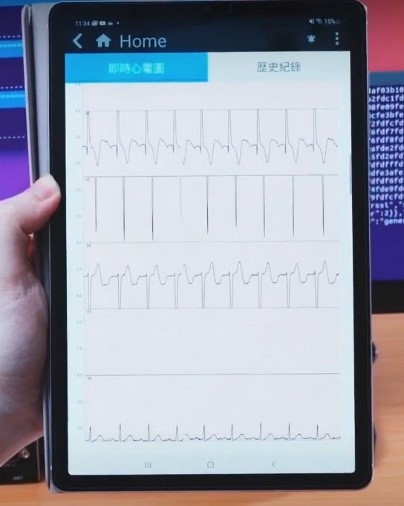

觀心自在—全功能無線多導極心電圖儀

觀心自在整合訊號處理及低功率藍牙通訊,提供長時間心電訊號量測,經閘道器上傳智慧雲端服務平台,完成資料的儲存,並發展十二導程訊號合成演算法、心房震顫偵測演算法與心肌梗塞偵測等人工智慧演算法,針對心電訊號做分析,能夠提供即時病症檢測及警示,整合成一智慧心臟健康照護物聯網平台。

團隊

國立陽明交通大學觀心自在團隊

產品規格

尺寸:63x46x12.3(mm)

軟體規格:智慧雲端服務平台

硬體元件:電極貼片、主機、閘道器

軟體規格:智慧雲端服務平台

硬體元件:電極貼片、主機、閘道器

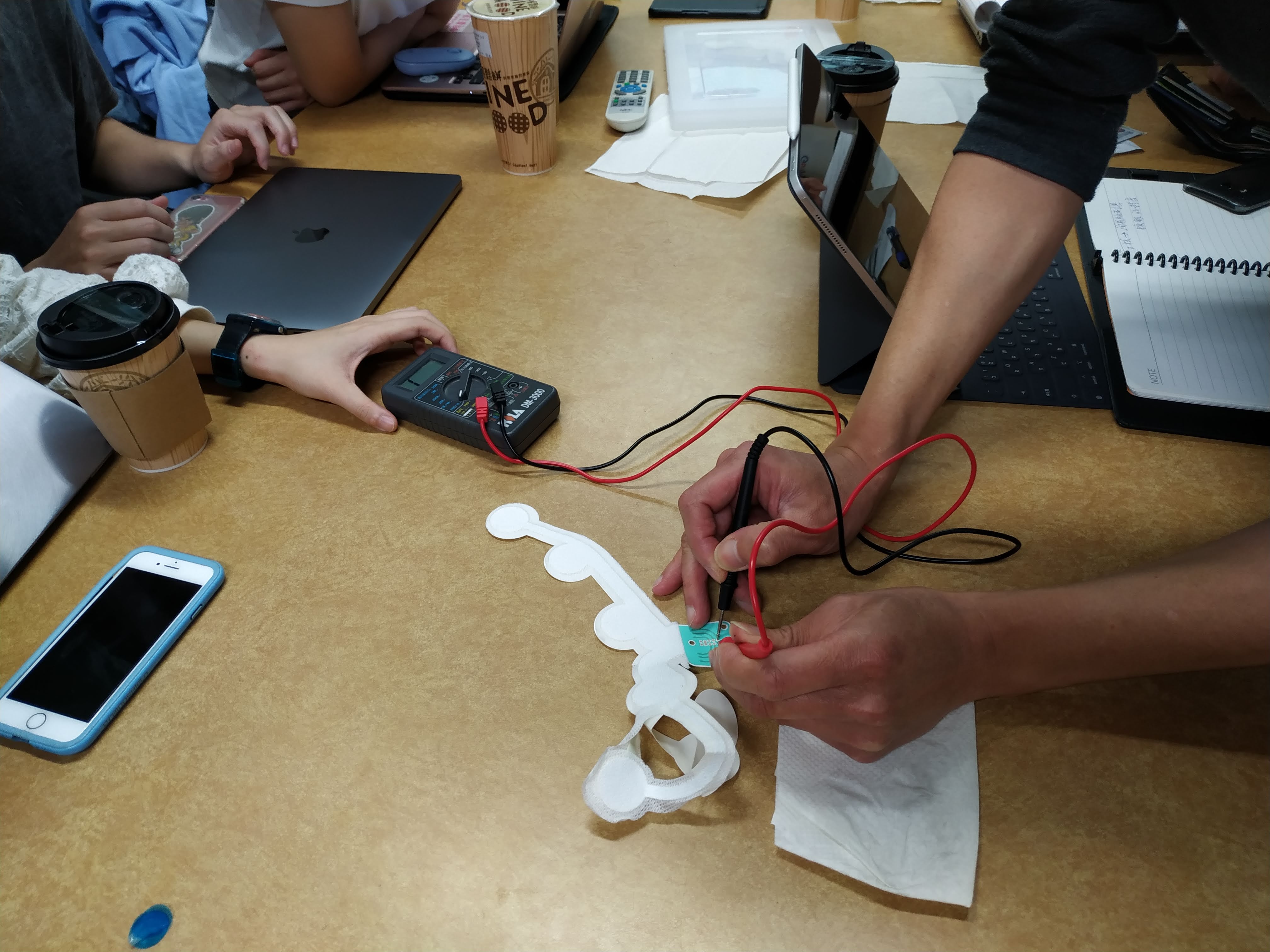

輔導流程

硬體設計協作

媒合服務團程創科技協做產品電路設計、PCB Layout、韌體、機構外觀設計與打樣;「金立電子」協助印製電極貼片。

軟體設計協作

媒合服務團世科國際協做APP。

輔導前

產品初代研發雛型

輔導後

產品雛型測試除錯

產品雛型人體測試實驗

智造顧問服務輔導後APP

產品安裝實測

可量產雛型

輔導案例

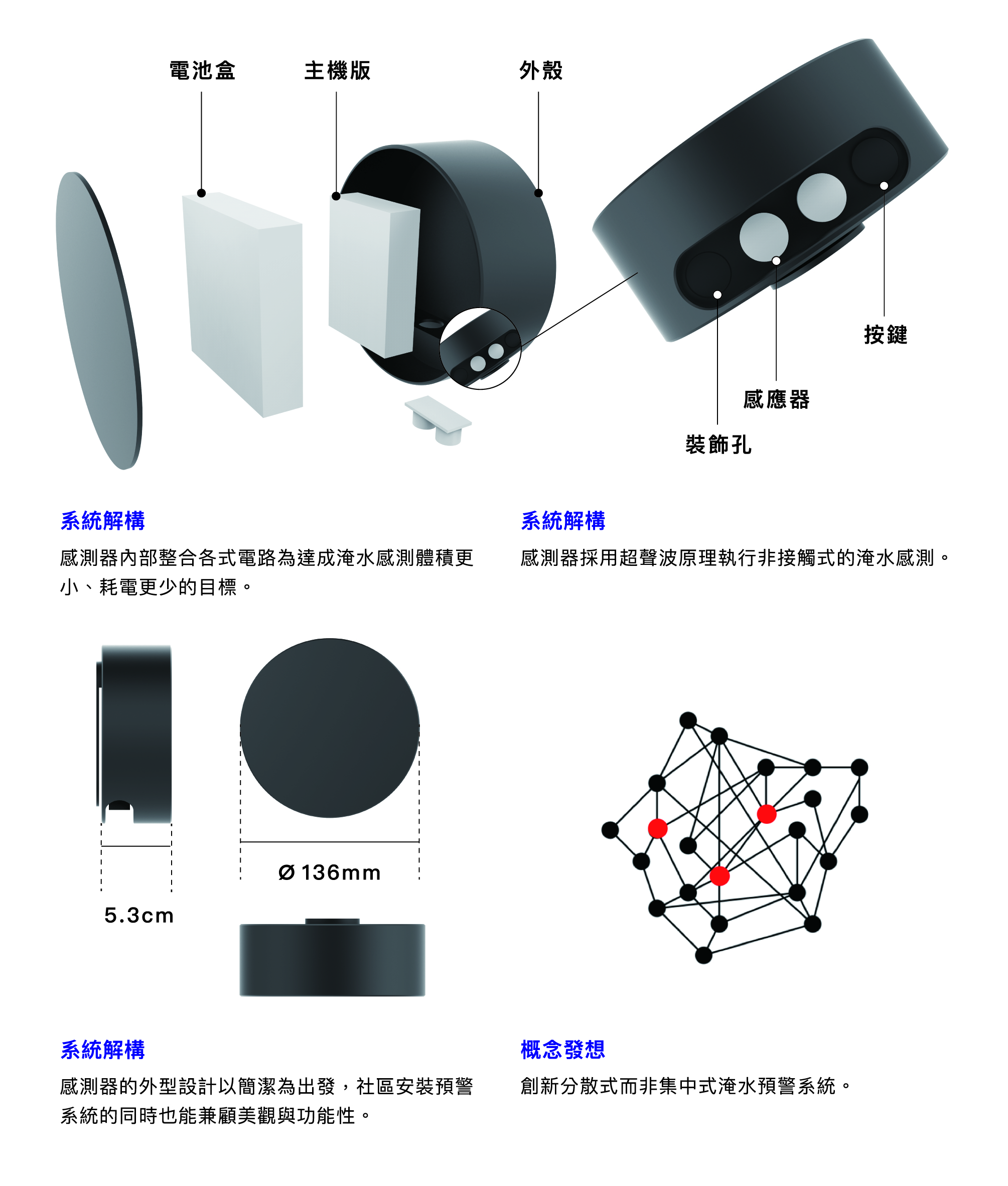

社區型快扣式淹水預警系統ECOMSNet- An Edge COMputing-based Sensory NETwork for flood warning

國立陽明交通大學以自主防災社區為中心,首度提出不同於傳統集中資訊(centralized)系統的分散式(decentralized)淹水預警系統。系統本身具有以下特點:(1)邊際運算技術與物聯網(Edge-Computing IoT, ECIoT) 結合之感測器可現地進行逐時淹水範圍之運算,有效降低資訊傳送之風險與提升防災應變之效率;(2)快扣(buckle-up)概念的應用可快速在目標區域進行系統安裝。事件過後,也可迅速拆卸回收,不但可節省維運成本,更可機動轉移至其他區域有效應用;(3)Chatbot與Beacon技術可推播個人化(personalization)相關資訊與減災避災作為,不但可提升社區自主防災之功能,更可降低災害風險與損失,減少災後重建費用。

團隊

國立陽明交通大學水科學多元應用實驗室THINKLab

產品規格

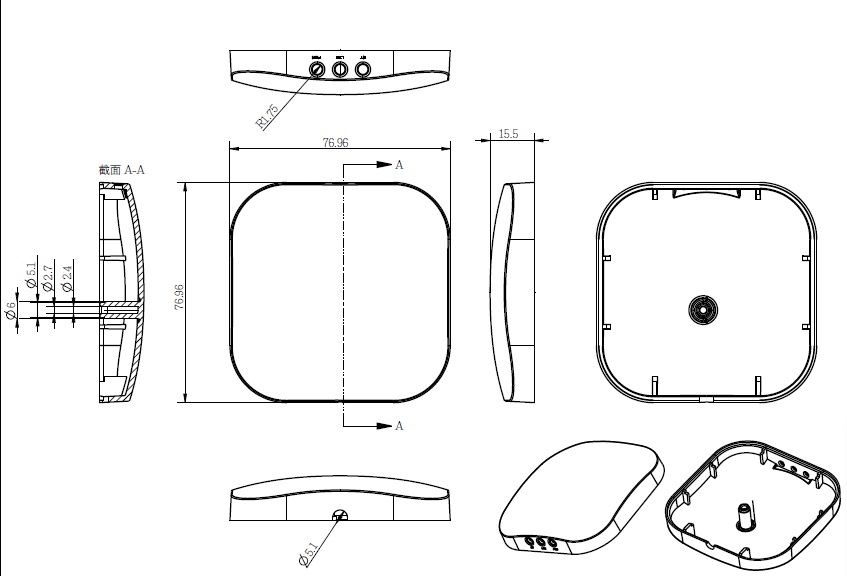

尺寸:直徑13.6cm/寬5.3cm

軟體規格:thingspeak&GCP

硬體元件:AM7020

軟體規格:thingspeak&GCP

硬體元件:AM7020

輔導流程

硬體設計優化

媒合服務團亞堤教育、冰山科技輔導產品電路優化。

機構外觀設計

媒合服務團墨設計協作產品機構外觀設計與打樣。

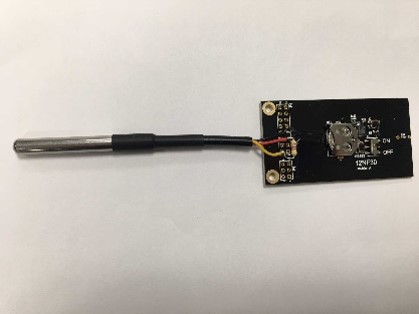

輔導前

產品輔導前研發雛型

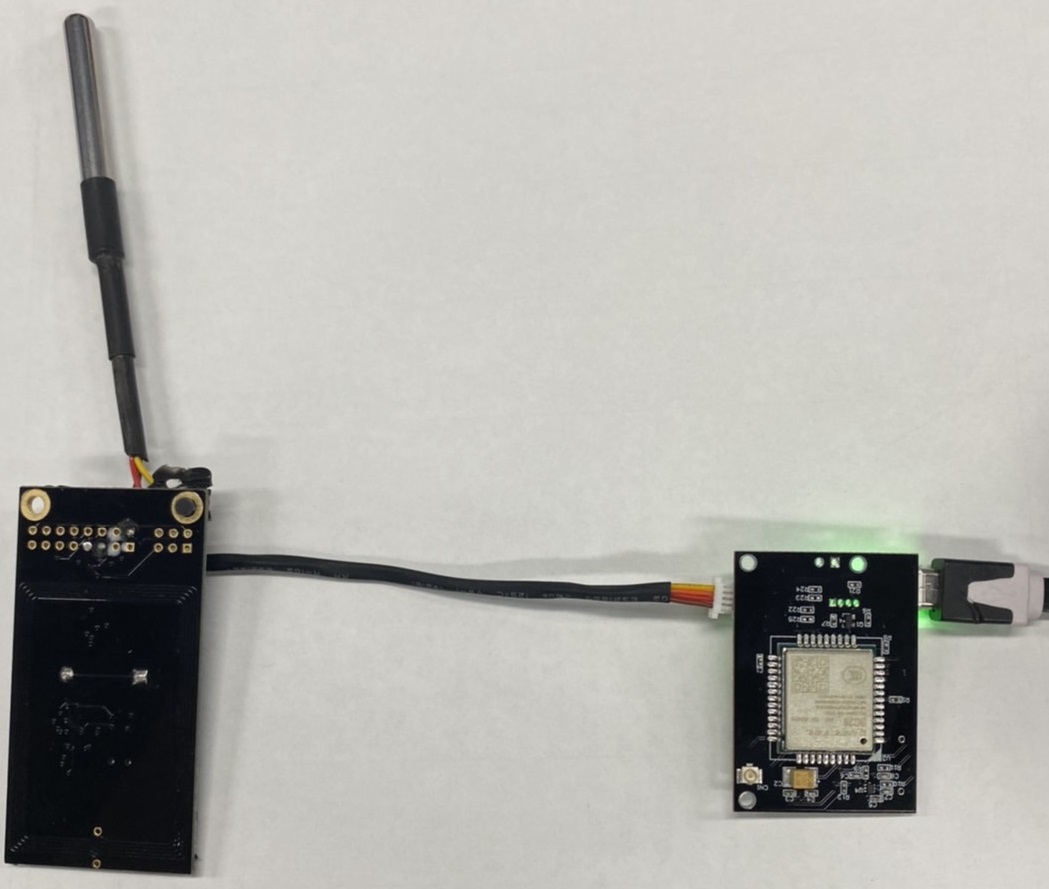

輔導後

智造顧問服務輔導後產品雛型

產品解構圖

產品安裝實測

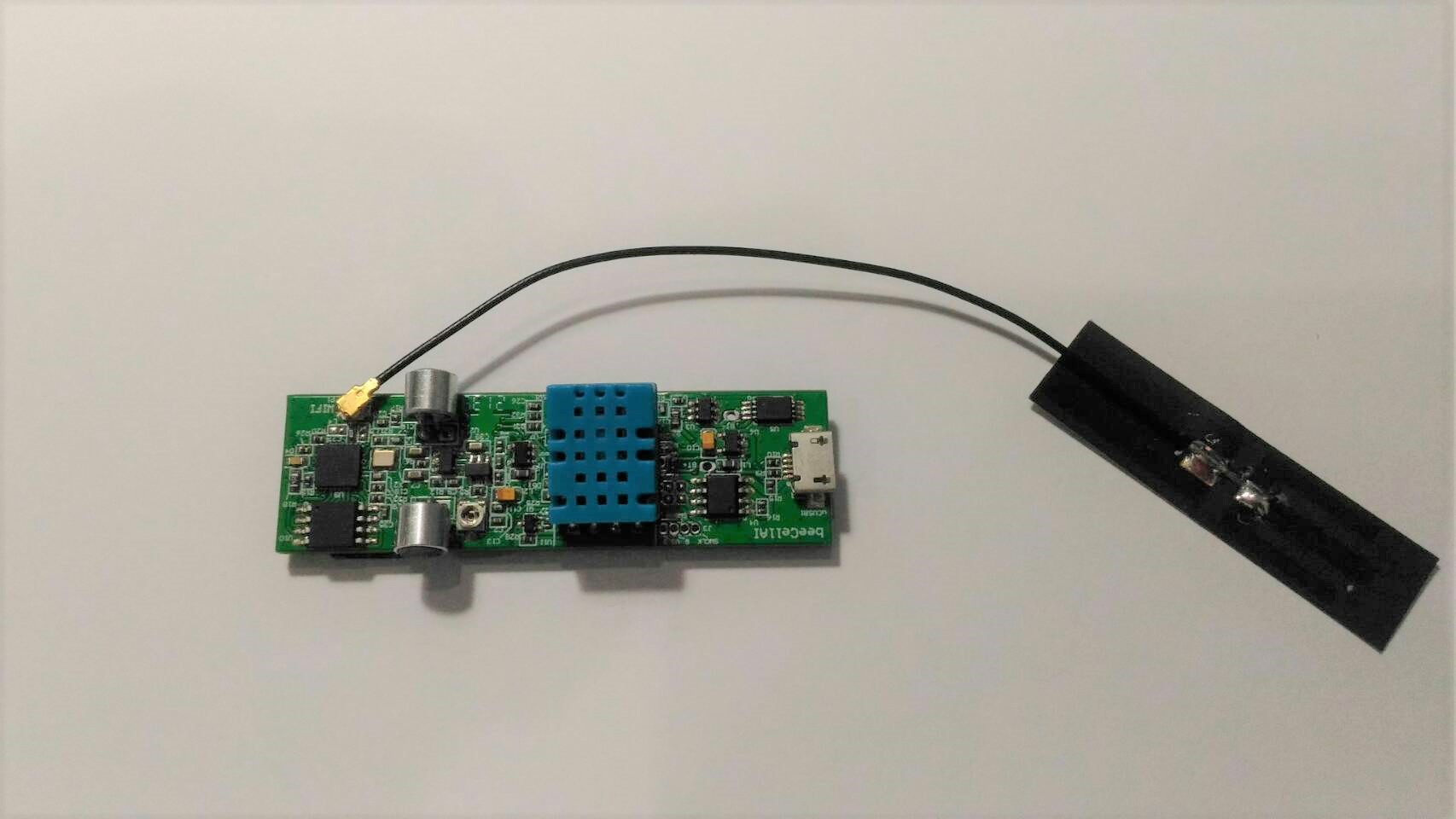

NB-IoT感測紀錄模組 / NB-IoT Sensor Logger Module

可量產雛型

輔導案例

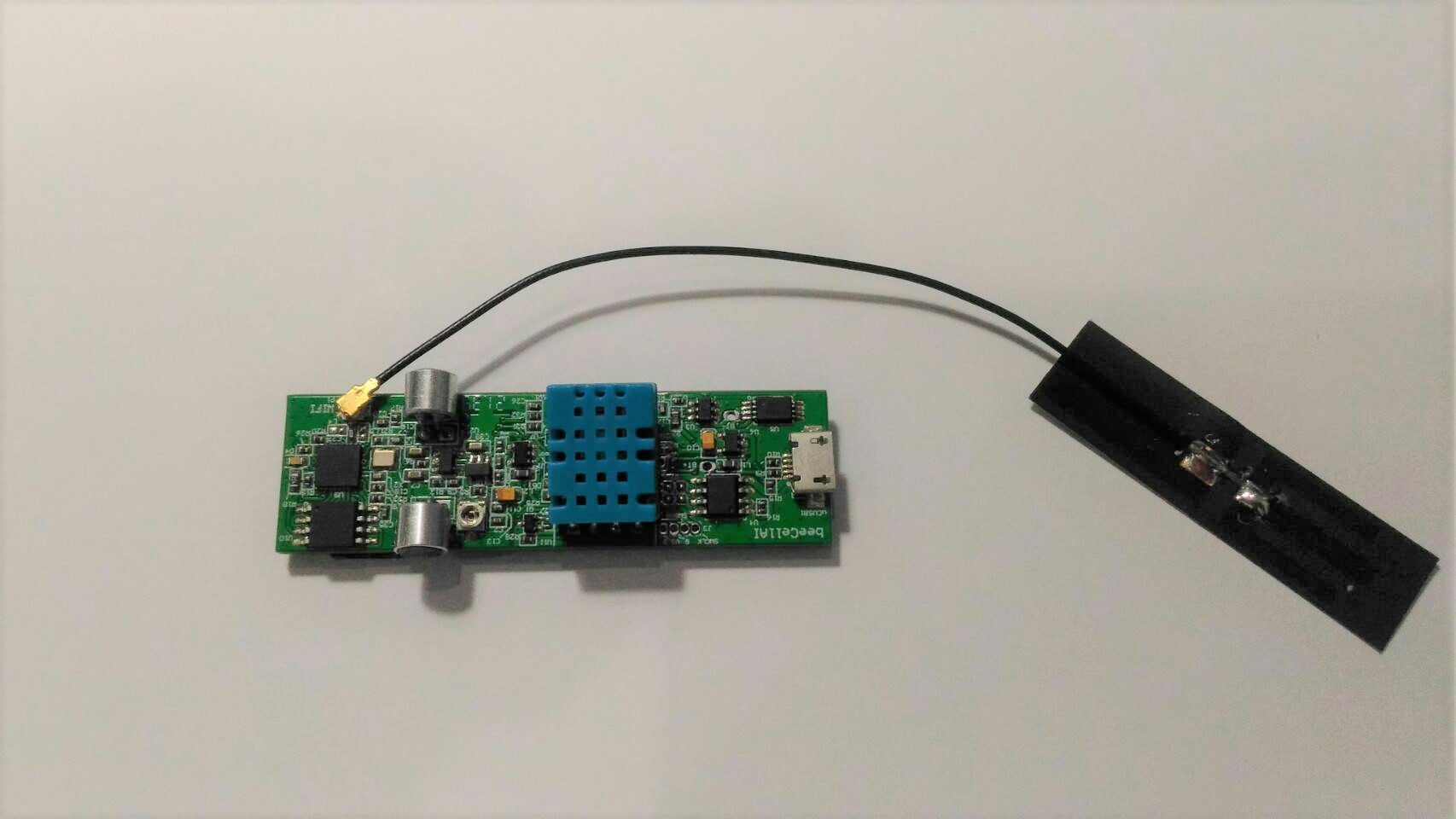

NB-IoT感測紀錄模組 / NB-IoT Sensor Logger Module

產品同時具有遠端通訊介面(NB-IoT)、近場無線通訊介面(NFC),具彈性的雙通訊介面模式,可更廣泛地支持不同應用(目前主要導入於廠房),取得即時溫度及歷史溫度紀錄;也可透過Web/App的方式做溫度監測、示警等服務、及大數據分析。

團隊

齊耀科技股份有限公司

產品規格

尺寸:長6.6cm寬4.3cm高1.6cm

軟體規格:雲端資料庫、APP

硬體元件:MTK MT2625

軟體規格:雲端資料庫、APP

硬體元件:MTK MT2625

輔導流程

國產化晶片選用

使用國產開發板DSI 2598+完成NB-IoT主板開發,打造物聯網通訊核心。

外觀設計

媒合服務團業師綠星光電協助完成CNC外殼設計及小量生產,瞄準食品冷鏈相關物聯網食品安全追蹤控管之推廣。

輔導前

產品開發原型

開發中產品原型

輔導後

導入DSI 2598+優化後產品及電路主體

綠星光電輔導後CNC外殼設計

電路板優化雛型,含模組更換、電路板小型化、電源優化

可量產雛型

輔導案例

物聯網蜂箱監測裝置

此裝置可以收集蜂箱環境資訊,如:溫、溼度、蜜蜂聲音。透過分析蜂鳴,幫助蜂農判斷蜂群健康狀況,藉以了解蜂群離巢之因素;採用了SVM (Support Vector Machine)分析法能高準確地判讀蜂巢內女王蜂的狀態。透過此裝置可使蜂場內勞動量降低、蜜蜂受干擾度減少,也可協助高齡蜂農、入門青農快速掌握蜂箱內蜂群狀態,並可解決蜂場缺工問題、提高生產效率,提升蜂蜜品質。

團隊

暨大資管資安與食安lab

產品規格

尺寸:長19mm / 寬65mm / 高8.5 mm

軟體規格:桌面應用程式

硬體元件:STM32F4、Arduino DHT11

軟體規格:桌面應用程式

硬體元件:STM32F4、Arduino DHT11

輔導流程

量產前診斷

媒合服務團進行個案諮詢給予技術評估、測試等建議,專家建議改善處包含,將聲音感測器更換為Arduino感測器以初步改善電量,並採用celp或adpcm壓縮技術處理音訊來降低資料量。

可量產優化實作

媒合服務團進行可量產規格擬定及實作,包含硬體規格優化、電路設計、PCBA開發,使用STM32F4,並將溫溼度、聲音蒐集、WiFi等感測器/模組進行整合,PCB微縮以符合使用環境。

輔導前

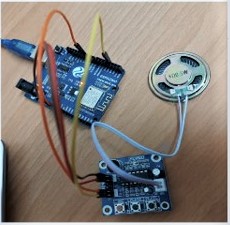

產品進案雛型,使用ReSpeaker 4-Mic Array與DHT22溫濕度模組

產品進案雛型,於南投縣蜂神養蜂場合作實證中

輔導後

經服務團建議,導入Arduino UNO作為實驗室版本,執行技術測試

電路板優化雛型,含模組更換、電路板小型化、電源優化

可量產雛型打樣

可量產雛型

輔導案例

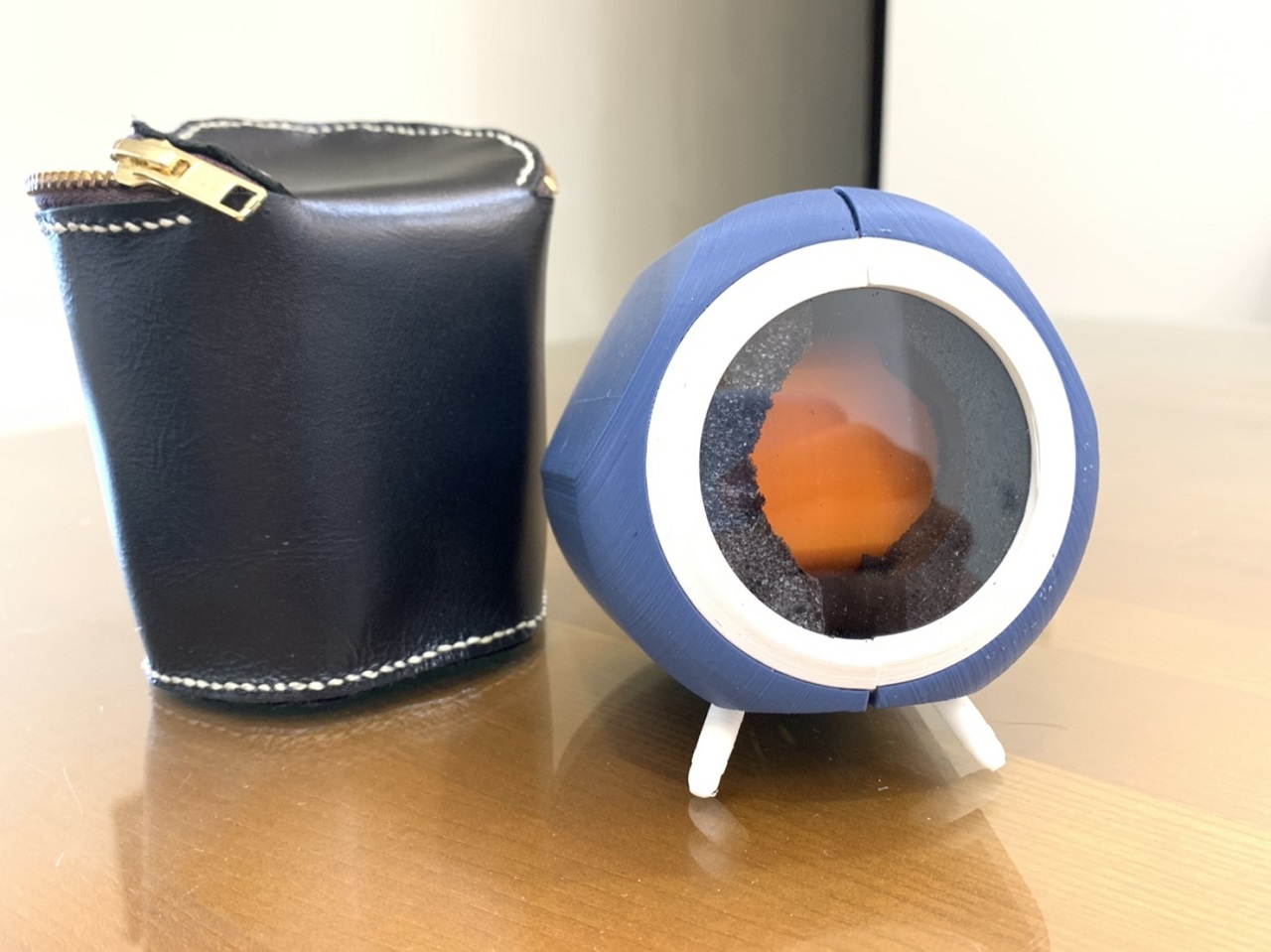

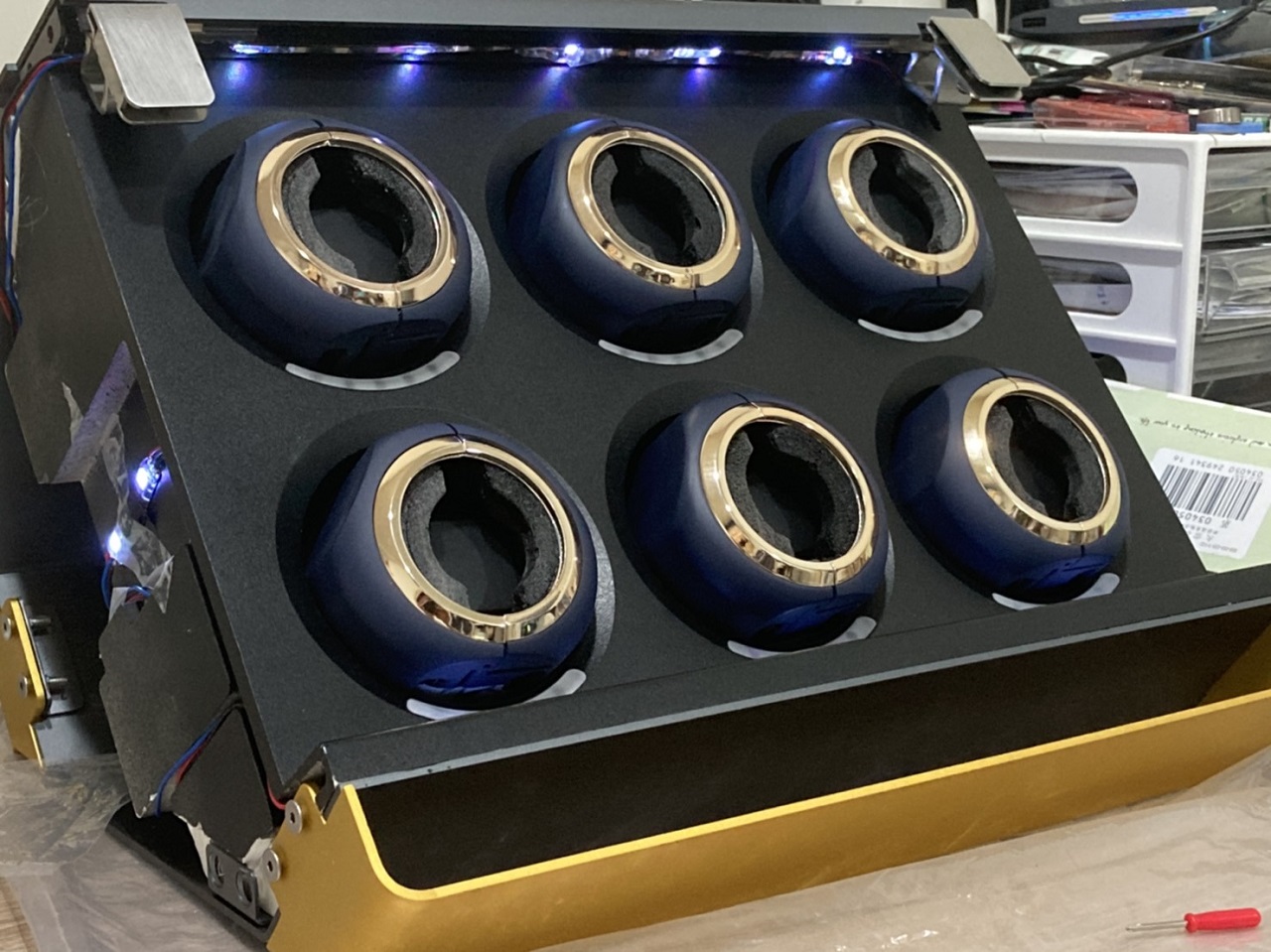

Tech&Watch智能手錶收藏盒

一台可以檢測與儲存機械錶錶況之收藏盒,整合收音裝置搭配演算法分析進行機芯檢測(穩定度、受磁度、動力),並整合智慧上鏈,將過往的「老師傅經驗」透過IoT技術具體化並得以傳承,同時搭配用戶專屬APP提供手錶使用者更好的自用與維運服務體驗。

團隊

為烽科技有限公司

產品規格

尺寸:40cm(長),32cm(寬),33cm(高)

軟體規格:網站、App

硬體元件:STM32-H7

軟體規格:網站、App

硬體元件:STM32-H7

輔導流程

機構外型設計

由服務團美集思設計協助進行產品機構與外型設計,並與電子電路整盒進行機構細部微調與打樣。

電子電路設計

由服務團系統整合業者協助進行電子電路驗證,並進行相關的POC、EVT、DVT等量產程序,持續朝PVT量產進行中。

韌體設計

由個人服務團劉晏維業師協助韌體開發,整合為烽科技專業know-how之商業邏輯於硬體電子電路,實現產品各項之控制服務。

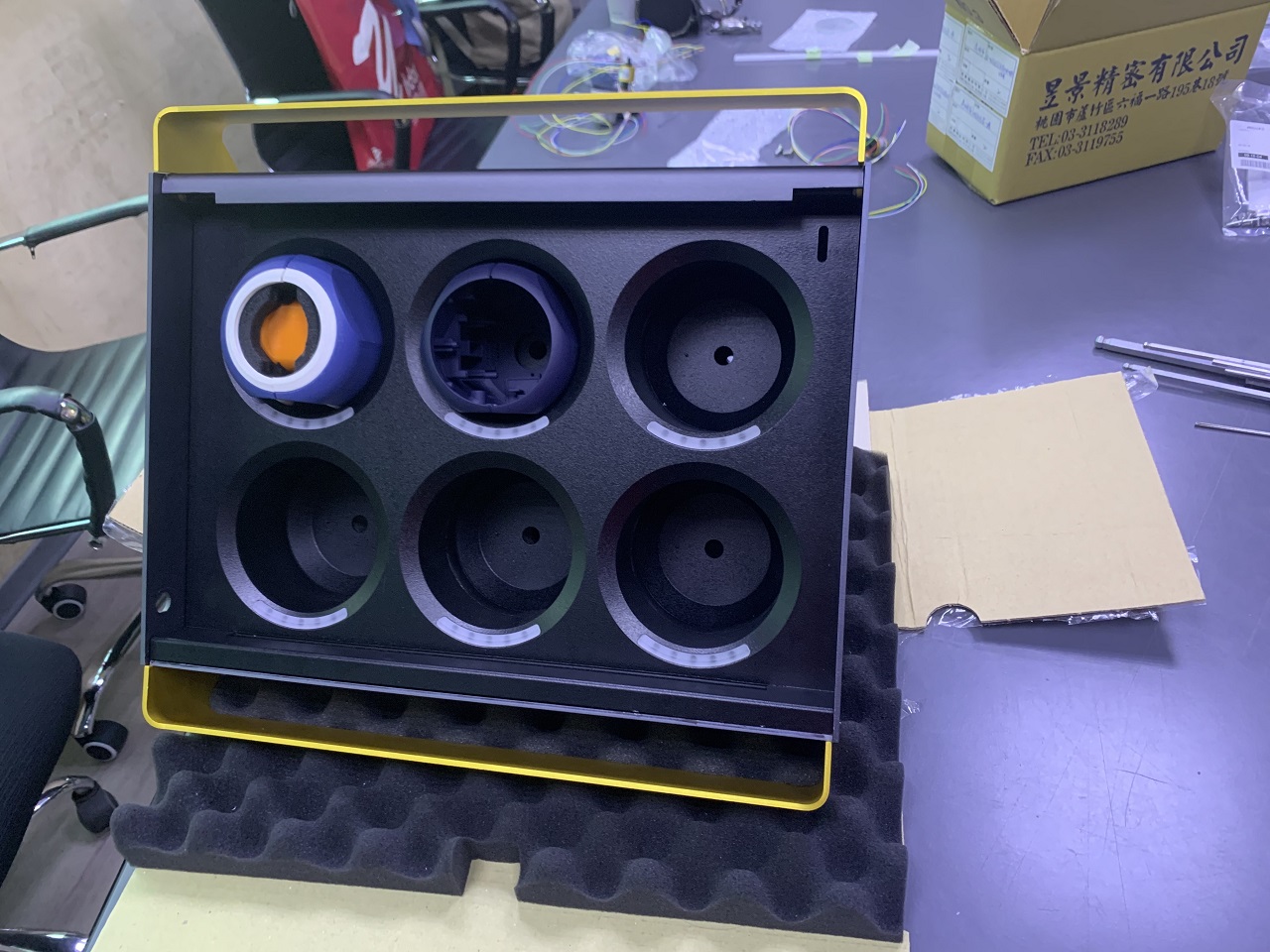

輔導前

傳統手錶收藏盒

使用Pi3結合Arduino進行演算法驗證

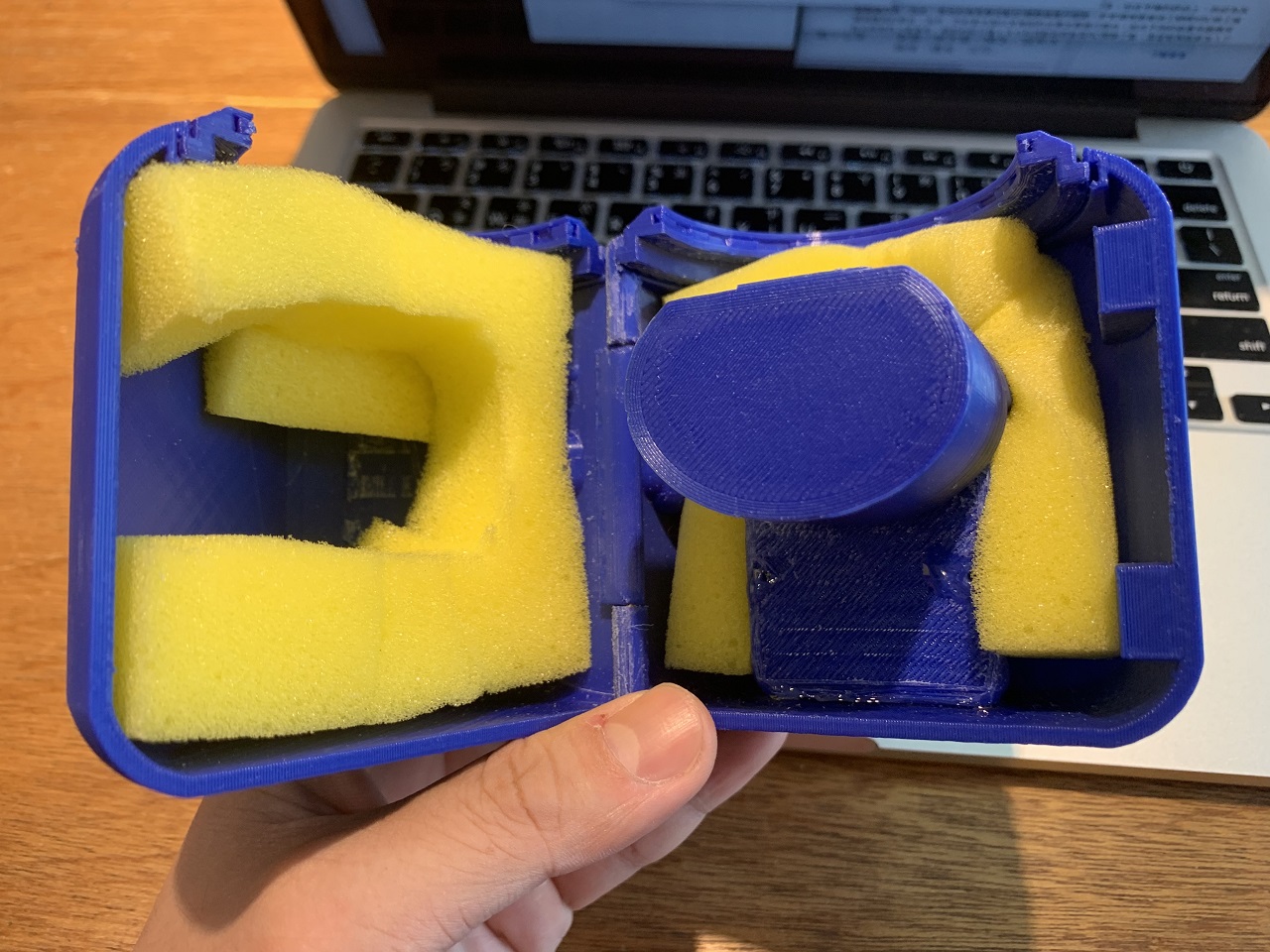

輔導後

產品構想外型與機構設計提案,歷經數次修改

產品構想外型與機構設計提案,歷經數次修改

第一版設計與打樣

第一版設計與打樣

第一版設計與打樣

電路設計、測試、電路板打樣

電路設計、測試、電路板打樣

電路設計、測試、電路板打樣

可量產雛型打樣

可量產雛型打樣

整合台灣IC、軟硬整合、設計、產製專業能量,O-take正式量產

可量產雛型

輔導案例

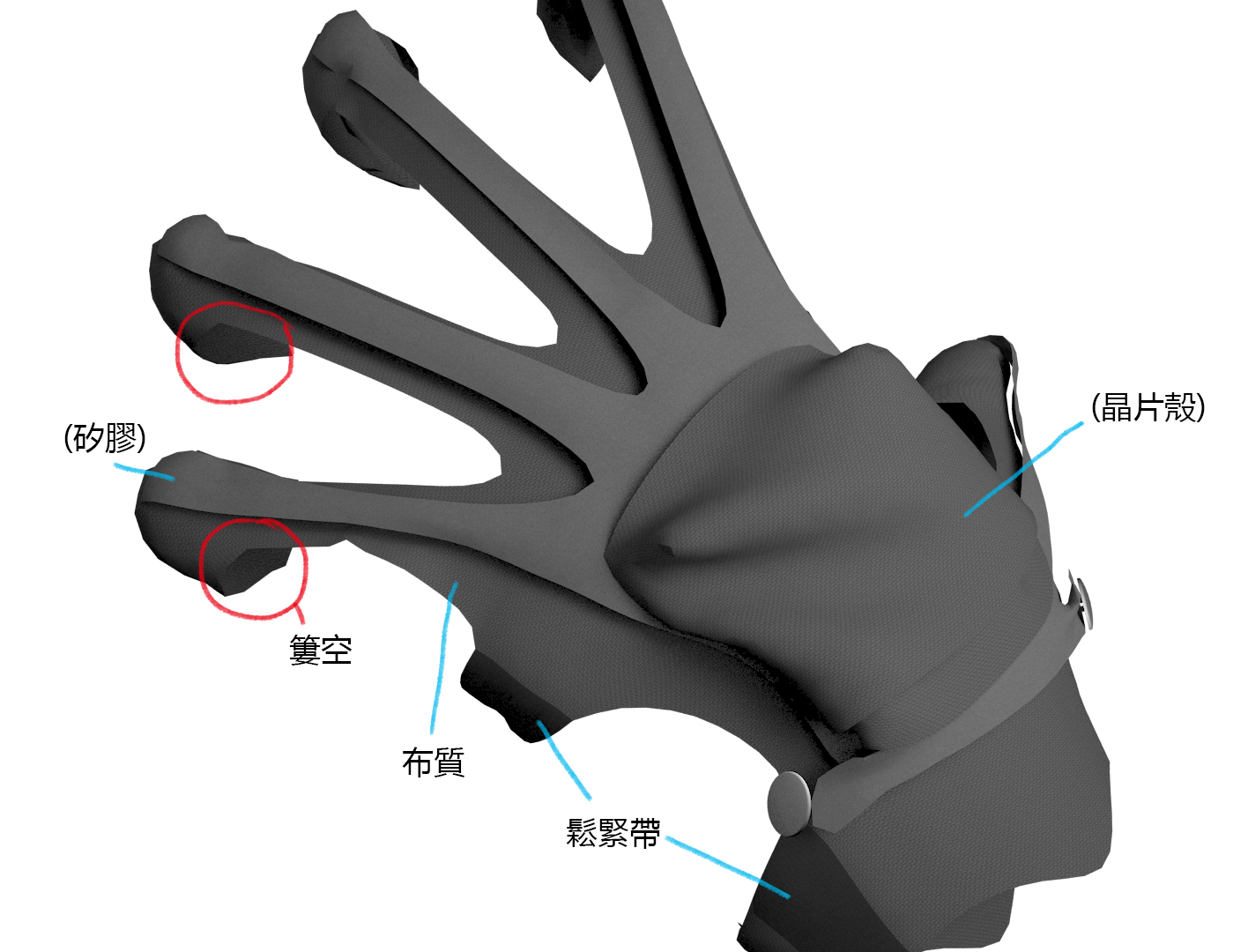

O-take高階虛擬實境控制手套

O-take高階虛擬實境控制手套,與VIVE整合取代手持搖桿,透過VR內容製作與真實空間整合運用,在虛擬實境裡對應每根手指的細微動作,讓使用者感受虛擬實境中真實掌握物品的使用,實現精密操作的互動能力。 同時,支援一人以上協同操作,提供精準空間定位,透過眼、耳、手、鼻、膚五感的互動體驗與訊息回饋,讓使用者更能快速適應VR世界的場景。 O-take得廣泛應用於職場訓練、重機模擬操作、場域導覽、品牌行銷等。

團隊

瑞意創科股份有限公司

產品規格

尺寸:25cm(長),13cm(寬),3cm(高)

軟體規格:桌面應用程式(VIVE相關應用程式)

硬體元件:瑞昱RTL8711AM

軟體規格:桌面應用程式(VIVE相關應用程式)

硬體元件:瑞昱RTL8711AM

輔導流程

國產硬體方案導入

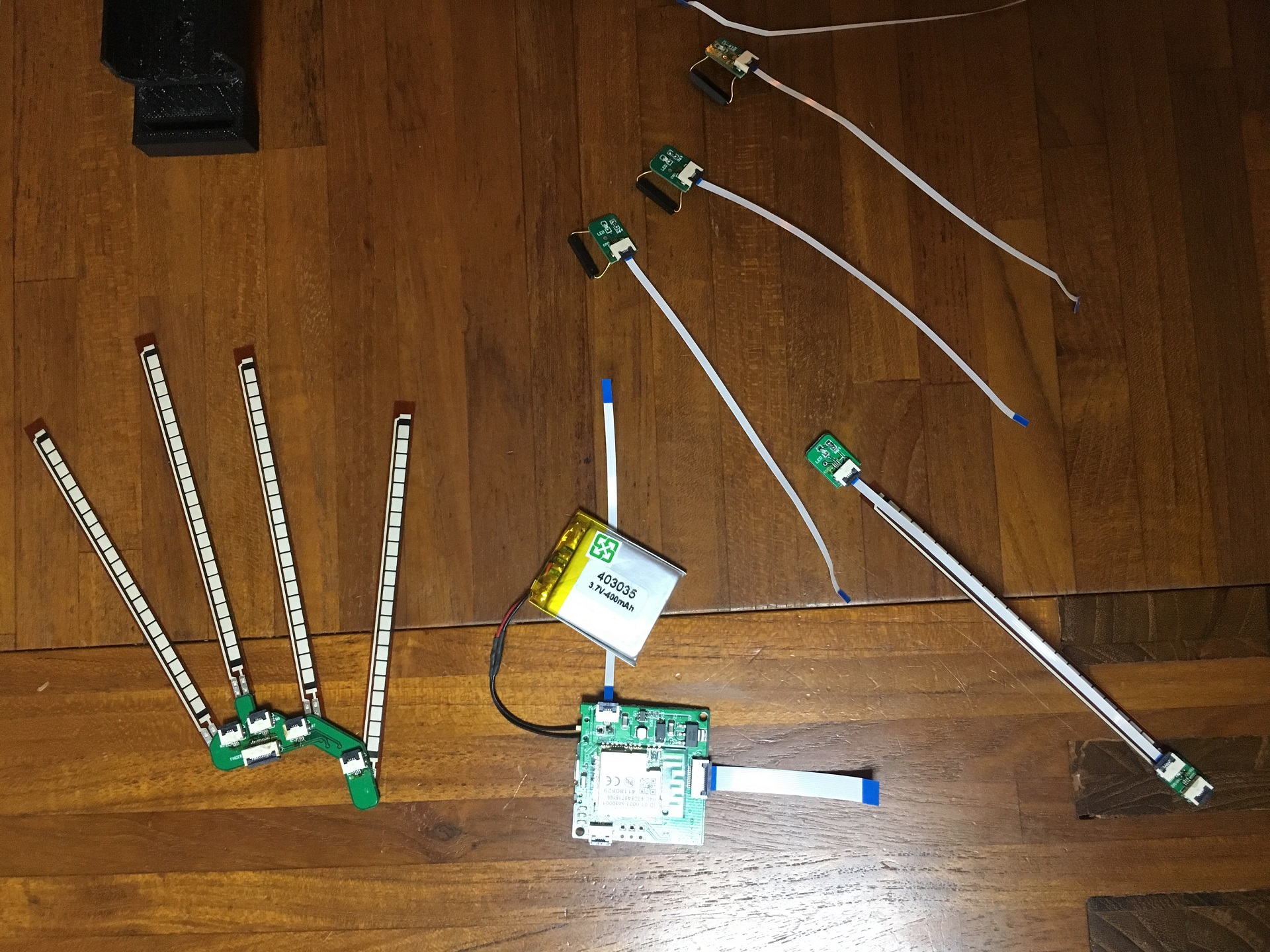

取代非量產化外接開源硬體方案,導入DSI5168開發板(RTL8711 AM晶片)導入驗證。

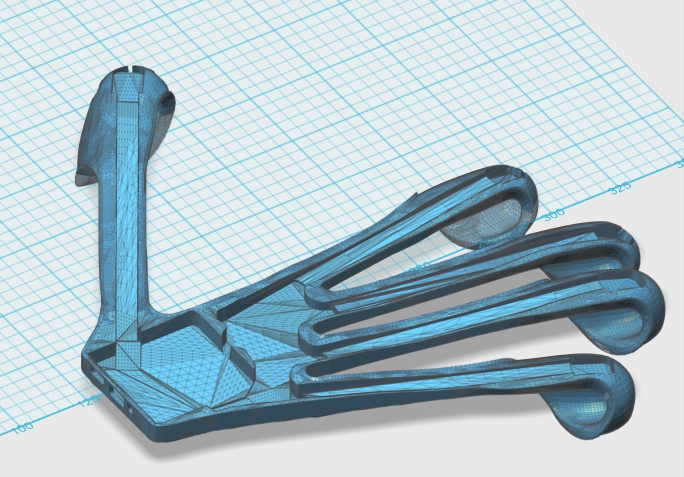

可量產規格設計與實作

媒合智造服務團進行PCB設計與Layout(奇俊科技、晶智電子)、ID/機構設計(黑設設計),產出第一代可量產雛型(並獲專利申請通過)。

商品化後送實作

後送工研院晶片整合服務中心(IisC)針對五指感測效能、產品續電力、外型進行整體性改良,並進一步產出量產版產品。

輔導前

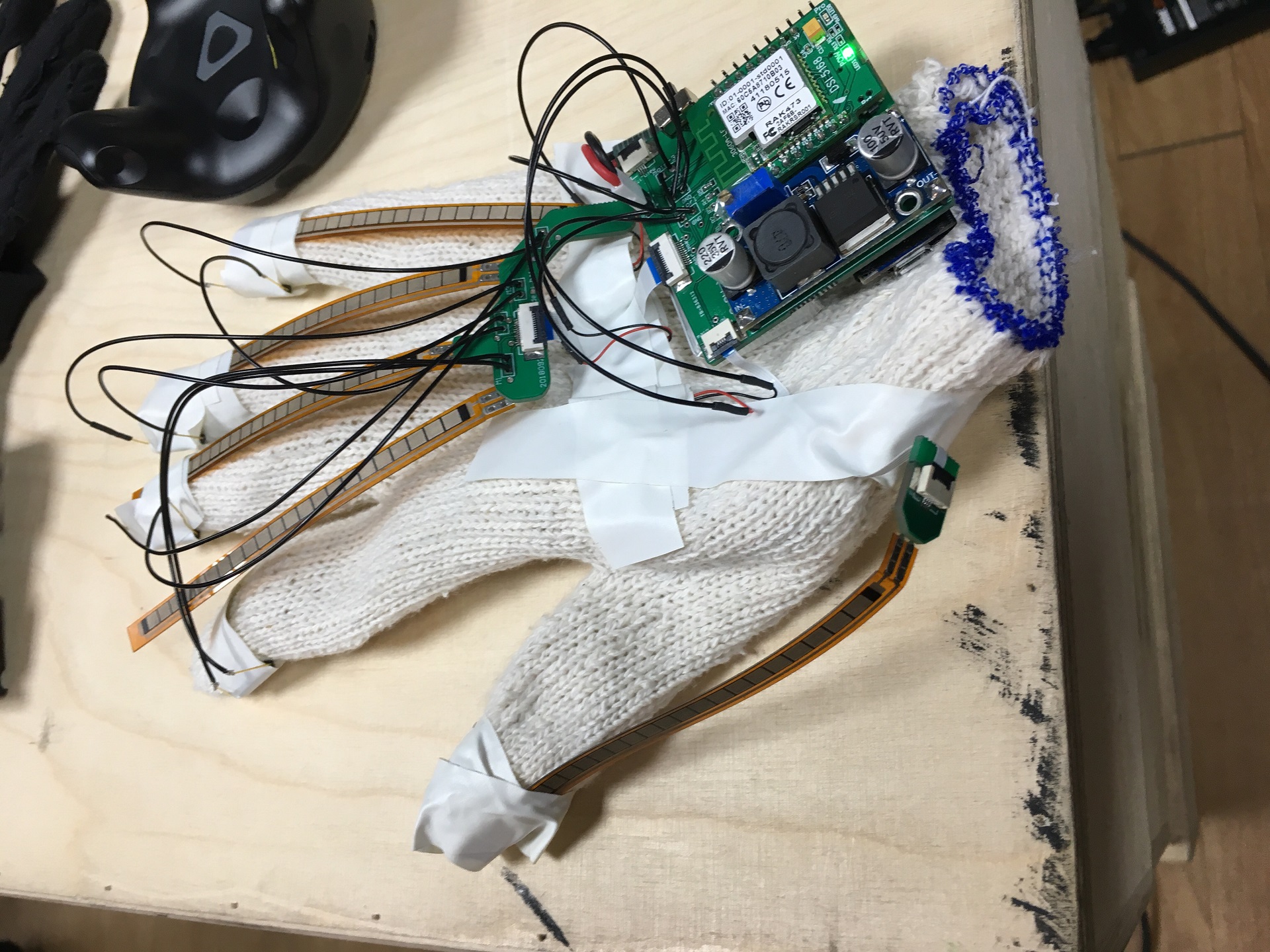

外接硬體開發板(採用ESP8266+Arduino),整合市售機車手套

輔導後

國產DSI 5168開發板(RTL8711 AM晶片)方案評估與導入驗證

硬體方案確認、PCB Layout與製作

機構與外型設計打樣

機構與外型設計打樣

機構與外型設計打樣

O-take可量產雛型於微風南山開幕與車商合作展式

O-take可量產雛型於微風南山開幕與車商合作展式

後送IisC商品化,O-take正式量產

後送IisC商品化,O-take正式量產

後送IisC商品化,O-take正式量產

後送IisC商品化,O-take正式量產

NB-IoT WhizConnect小量試產,啟動場域實證

可量產雛型

輔導案例

NB-IoT WhizConnect

NB-IoT WhizConnect是與近端藍牙產品連接的NB-IoT傳輸閘道器,主要串接世大智科公司旗下「天才家居」系列產品,包含:天才床墊WhizPad、天才坐墊WhizSeat、天才呼叫WhizTouch等,並額外開發可與市售手環、血糖血壓機、溫溼度記等裝置串聯,透過NB-IoT傳輸方式將產品偵測資訊上傳雲端。

團隊

世大福智科技股份有限公司

產品規格

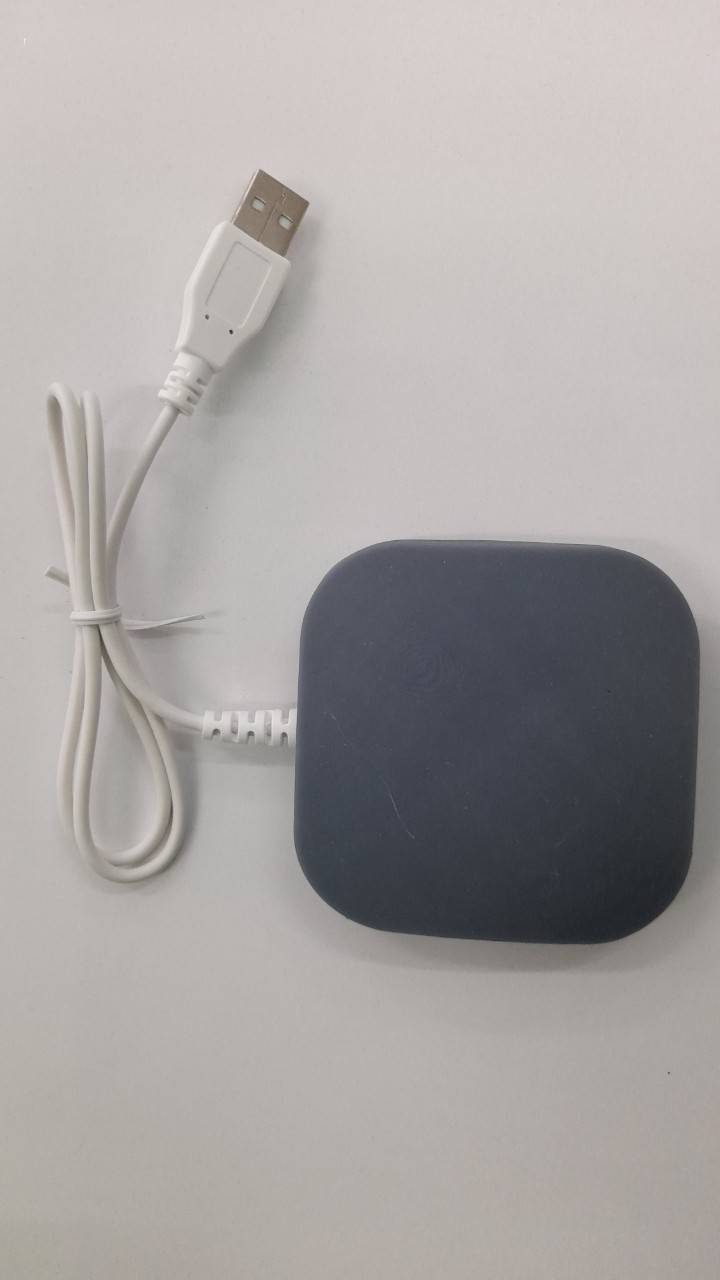

尺寸:7cm(長),7cm(寬),2cm(高)

軟體規格:Amazon Web Services、Flutter App

硬體元件:STM32L476RGT6、BG96、MDBT42Q

軟體規格:Amazon Web Services、Flutter App

硬體元件:STM32L476RGT6、BG96、MDBT42Q

輔導流程

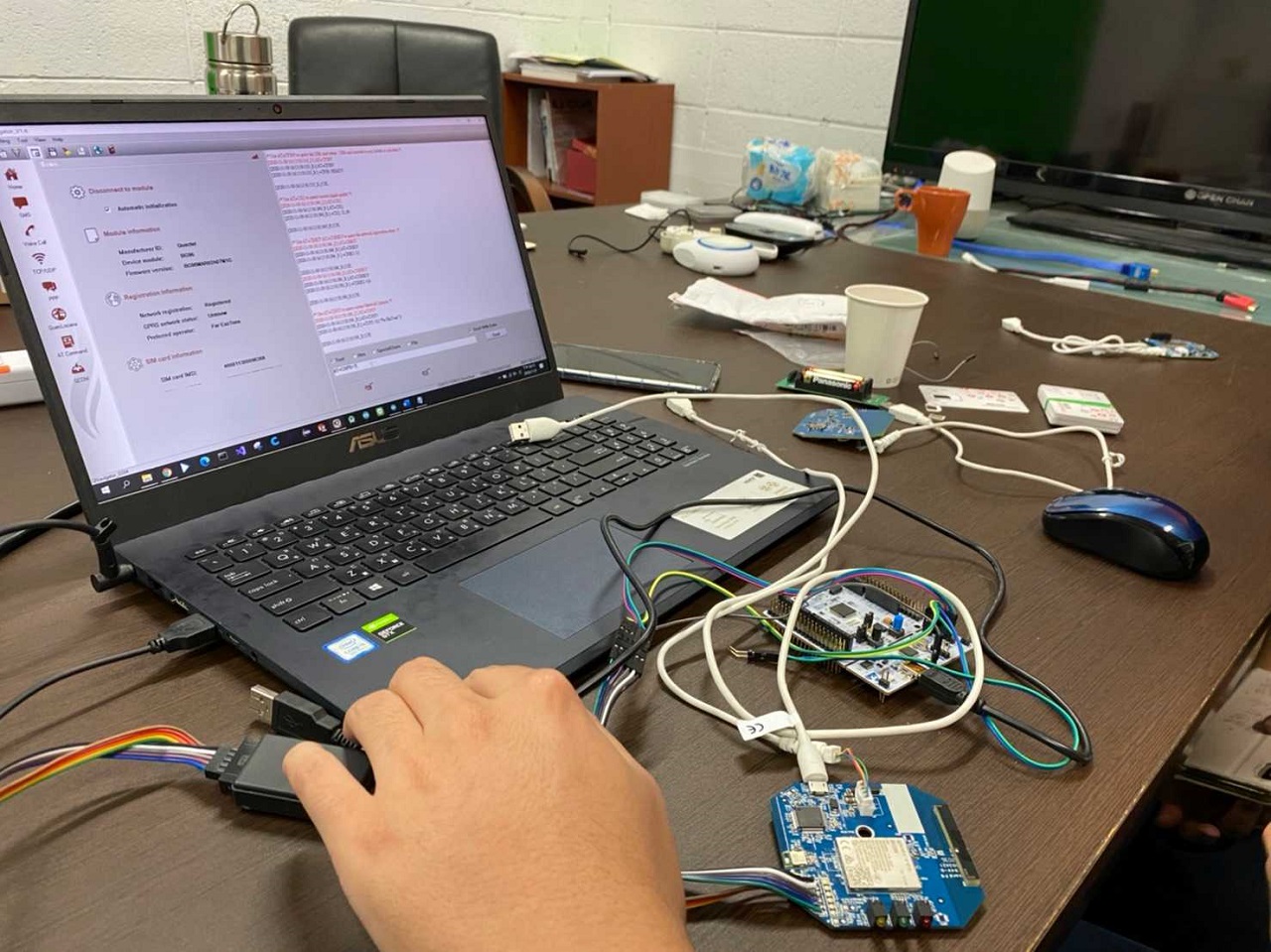

硬體規格優化

媒合智造服務團昱景科技進行PCB優化設計,降低料件成本;並客製化產品天線,機構配置調整,提升產品傳輸品質與距離。

可量產雛型打樣

媒合智造服務團金運科技進行PCB Layout實作,產出PCBA並整合機構外殼進行產品功能實測,進行小規模場域實證。

輔導前

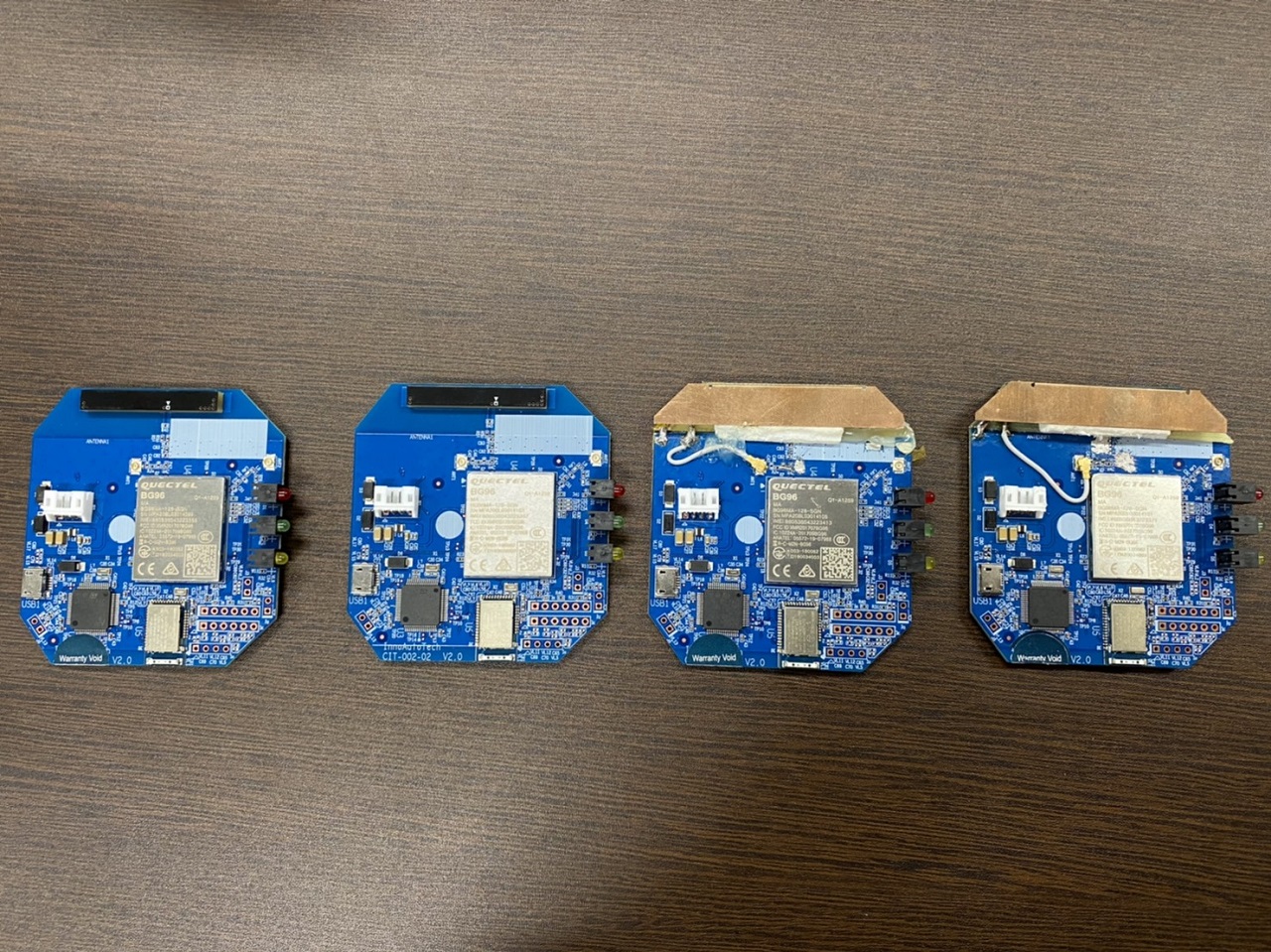

第一版自行試製PCBA,體積過大需微縮

第二版委外製作,藍牙與NB-IoT WhizConnect傳輸距離、強度仍須提升

輔導後

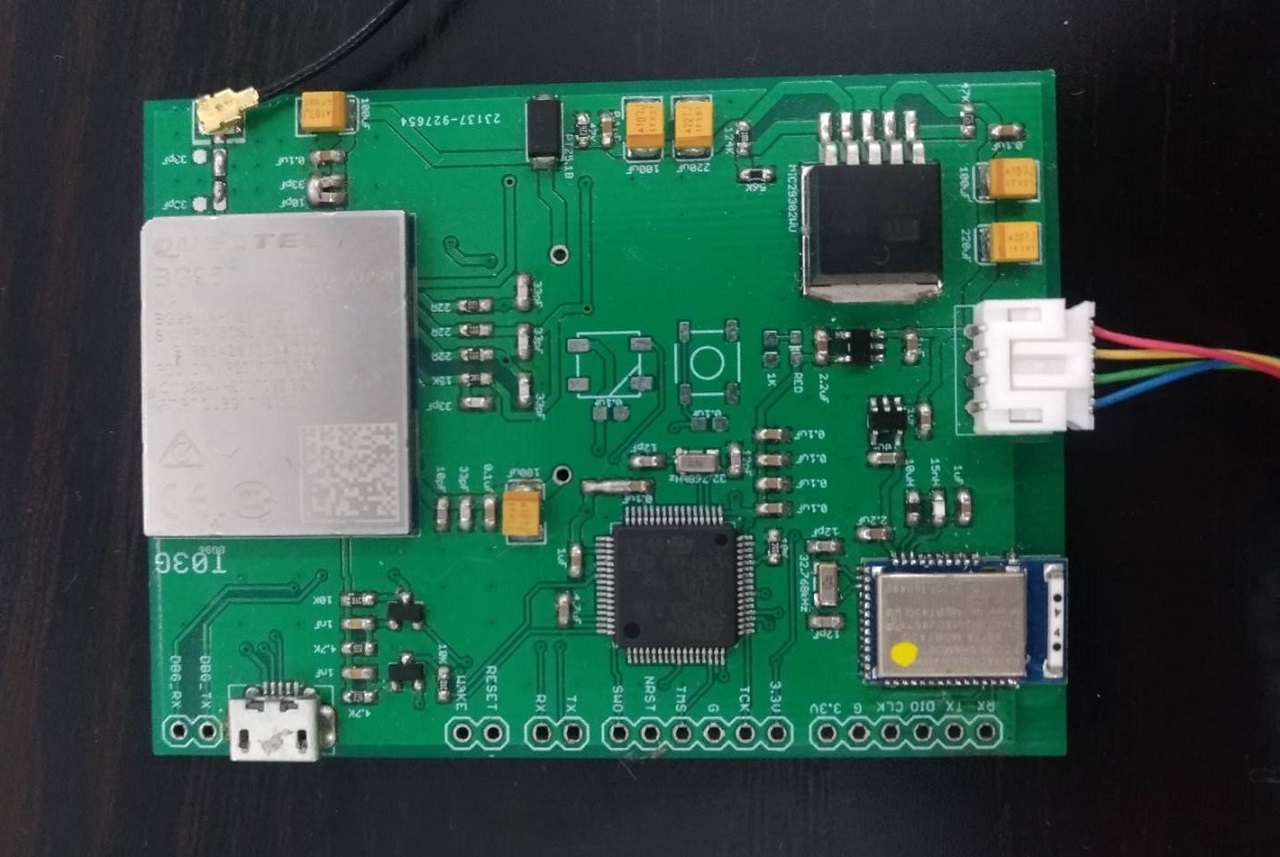

電路優化設計與PCBA效能測試

優化後之電路板雛型打樣

搭配電路板進行機構與外型設計與外殼打樣

搭配電路板進行機構與外型設計與外殼打樣

NB-IoT WhizConnect小量試產,啟動場域實證

「農業大數據擷取平台」導入格園社企進行驗證

可量產雛型

輔導案例

農業大數據擷取平台

農業大數據擷取平台之開發則是起因於針對農業產業上缺乏可以整合大部分感測器及設備之中介裝置,透過Gateway可整合農業上常用之感測器及設備控制介面,並且加入簡單邊緣運算功能,並提供多種無線網路傳輸方式將數據送回後端平台。

團隊

邁森科技股份有限公司

產品規格

尺寸:175 mm x 110 mm x 55 mm

軟體規格:APP、web應用程式

硬體元件:Raspberry Pi 3B+, 4B

軟體規格:APP、web應用程式

硬體元件:Raspberry Pi 3B+, 4B

輔導流程

國產化晶片選用

以聯發科NB-IoT MT2625模組,擴充樹莓派系統,打造產品物聯網通訊核心。

電路整合技術

後送IisC針對農業數據感測器及硬體進行整合優化及模組化,並重新設計電路系統縮小化,提升電路穩定度,讓農民與場域應用更便利。

軟硬整合

串接ideas Hatch雲端數據收集平台,並整合產品-種苗培育皿(溫濕度、CO2),建立智慧種苗培育完整解決方案。

輔導前

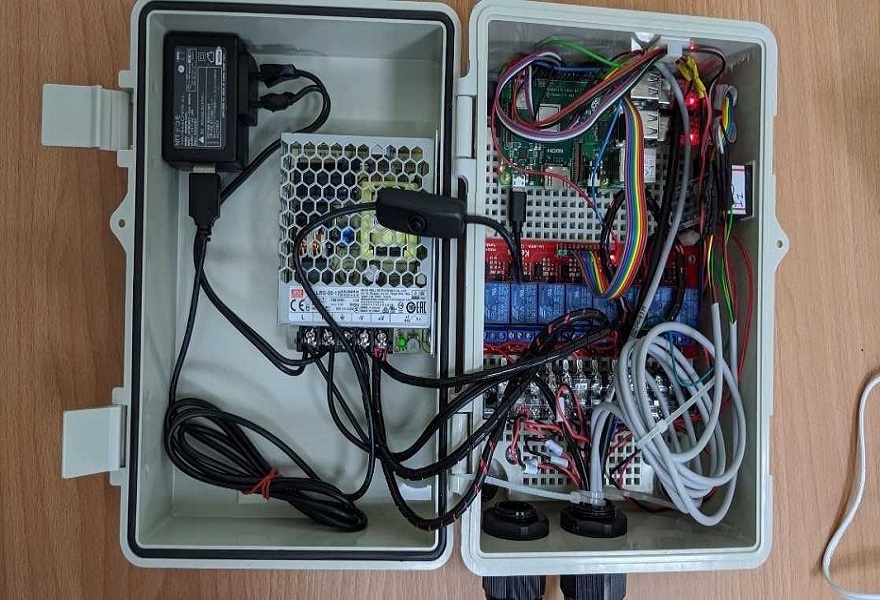

農業大數據擷取平台進案狀態(採用Raspberry Pi 3B+, 4B)

輔導後

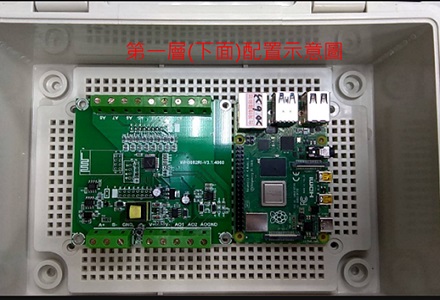

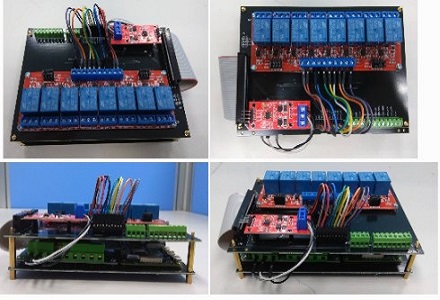

農業大數據擷取平台優化擺盤示意(上層)

農業大數據擷取平台優化擺盤示意(下層)

農業大數據擷取平台專用轉接板設計成品

優化種苗培育環控系統,建立高經濟作物培育機制

可量產雛型

輔導案例

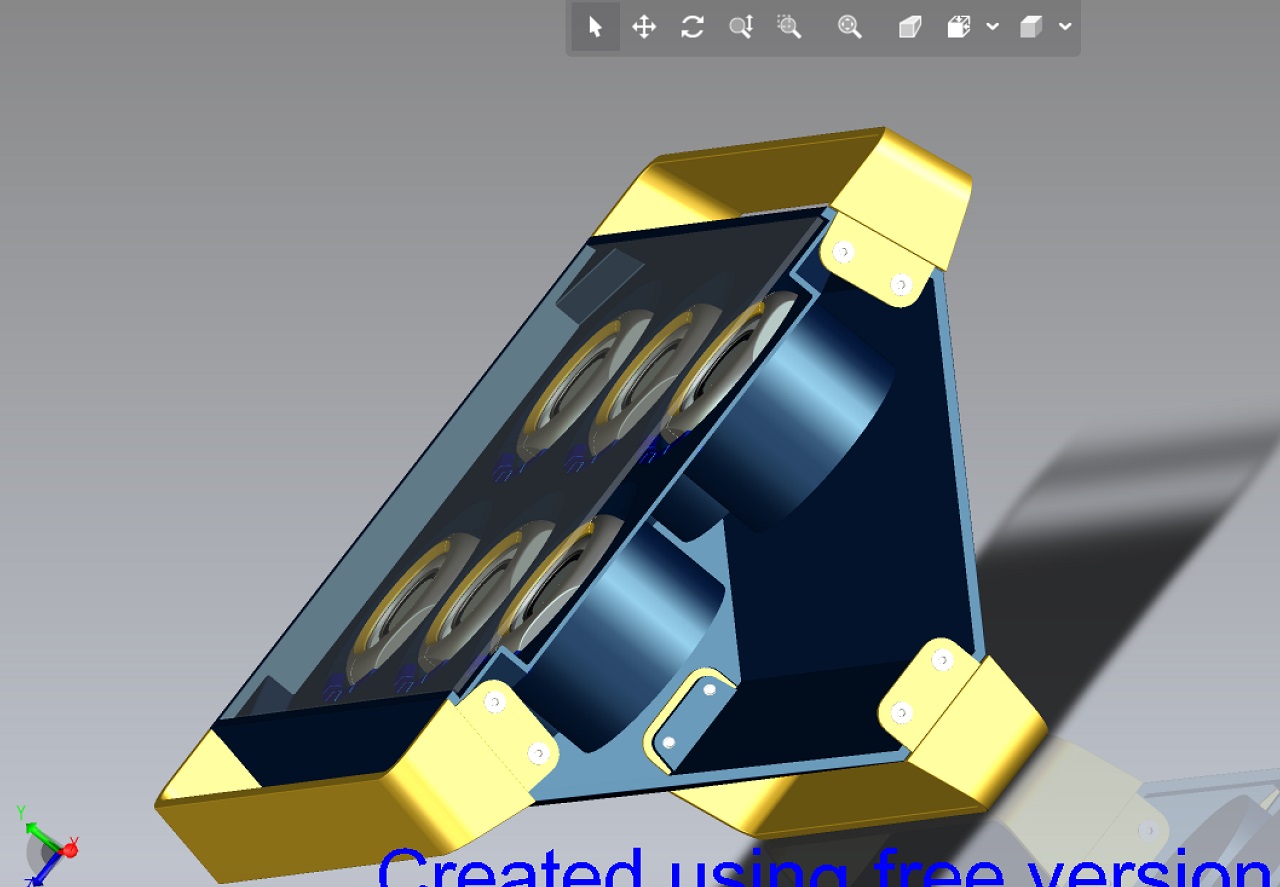

智能種苗培育設備

本產品可整合氣體數據,透過無線傳輸即時回應系統,記錄種苗栽培容器內之環境參數並進行各類分析服務,協助種苗栽培者即時掌握容器內微氣候狀況以及判斷種苗生理狀態,進而對客戶提供各項客製化培育服務及歷史數據;透過後端平台蒐集並累積種苗栽培容器內之環境參數,可建立即時解讀種苗培養過程中之生長及生理狀態,量化種苗生長過程中所表達的訊息,並歸納出其臨界闕值,進而分析出不同生長參數對種苗生長生理之影響。

團隊

邁森科技股份有限公司

產品規格

尺寸:重新設計成可加入32.57mm*19.5mm*8.5mm之氣體感測器,下部容器尺寸修改為直徑 150mm * 高 138mm之圓柱體

軟體規格:APP數據監測分析軟體

硬體元件:Nordic-NFR51822

軟體規格:APP數據監測分析軟體

硬體元件:Nordic-NFR51822

輔導流程

雛型試製資源

媒合智造設計服務團「艾特克科技」進行外觀設計優化,解決CO2外流問題,進行機構重新設計。

系統整合開發

整合109年度新提案「農業大數據擷取平台」運算機能,針對場域業者之需求進行種苗設備客製化設計,並串接IDEAS Chain後台,進一步優化種苗培育環控系統,建立高經濟作物培育機制。

輔導前

原外觀為自行鑽孔設計,導致CO2感測精準度不足

整合市售模組進行數據蒐集與運算

輔導後

媒合服務團「艾特克科技」進行外觀設計優化

IisC協助提高硬體組裝良率,加速商品化速度

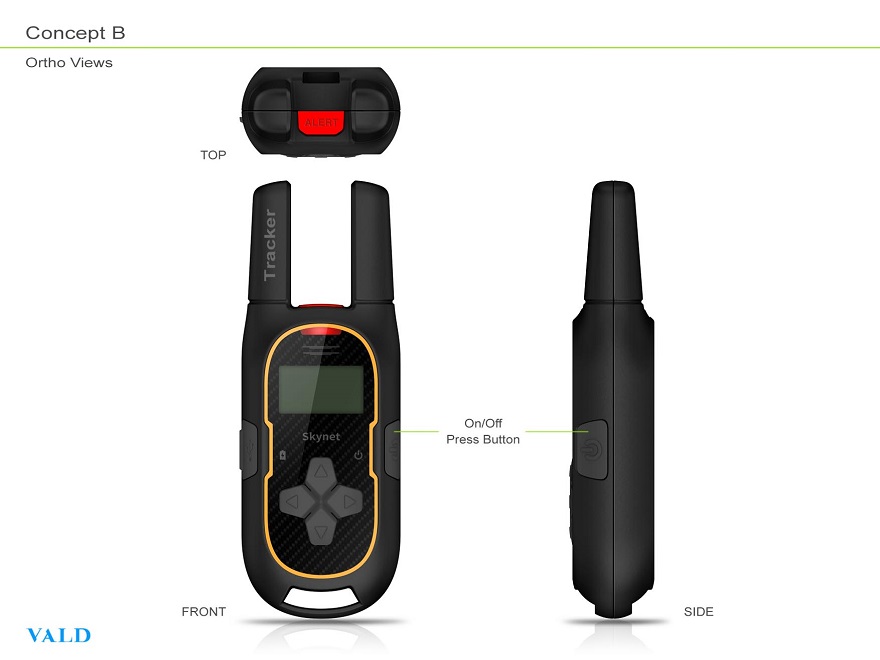

登山救命器主機/子機以「多點超距」的技術進行安全防護

可量產雛型

輔導案例

登山救命器

登山救命器主機/子機以「多點超距」的技術進行安全防護,形成團隊安全網,可提供給山難救援的搜索隊員與登山客使用。透過Sub-G Mesh的架構,結合藍芽與手機APP可以在山區進行無網路訊息傳輸,當山友爬山遇到意外時,可有效提升被搜救的機率。

團隊

行翼網通有限公司

產品規格

尺寸:64*150 / 40*57 (mm)

軟體規格:APP

硬體元件:Skynet RTM-100

軟體規格:APP

硬體元件:Skynet RTM-100

輔導流程

天線設計優化

針對天線進行電路設計與重新打件,成功將傳輸距離從50公尺增加至2,400公尺。

雛型試製資源

媒合智造設計服務團進行登山救命器子機之外型設計(進化論設計)與樣品打樣(穎聲鋼模)。

場域實證

前往北部(平溪山區)、中部(惠蓀農場)、南部(涼山瀑布)進行產品實地測試,可在實地完成各項訊息之傳輸,完成POS驗證。

輔導前

登山救命器主機輔導前

輔導後

完成主機天線重新設計

完成登山救命器子機外型設計與打樣

登山救命器主機/子機

工具機機況讀取棒之輔導後硬體規格

可量產雛型

輔導案例

工具機機況讀取棒

工具機機況讀取棒(低成本smart machine box),顧名思義為連結工具機,讀取相關參數、作動情形,以WiFi介面透過網際網路傳送並儲存至雲端資料庫,以利後續相關演算。普通工具機即可轉為智慧機械。由於中部地區是工具機生產重鎮,因應工業4.0啟發了雨辰科技開發工具機況讀取棒,雨辰科技利用嵌入式系統晶片開發,本產品無作業系統,不易藏木馬病毒,低耗電,架構簡單,品質穩定,安全又低成本。可與工廠ERP系統結合直接介接,目前實證測試已經可以與發那科、三菱等大廠工具機直接介接,接收工具機即時資訊及運轉狀況,如稼動率、主軸轉速、負載、運轉中、停機、告警訊號等等。

團隊

雨辰科技實業社

產品規格

尺寸:80mm(長),60mm(寬),15mm(高)

軟體規格:Web應用程式(雲端工廠監控)

硬體元件:開發板(ESPRESSIF)

軟體規格:Web應用程式(雲端工廠監控)

硬體元件:開發板(ESPRESSIF)

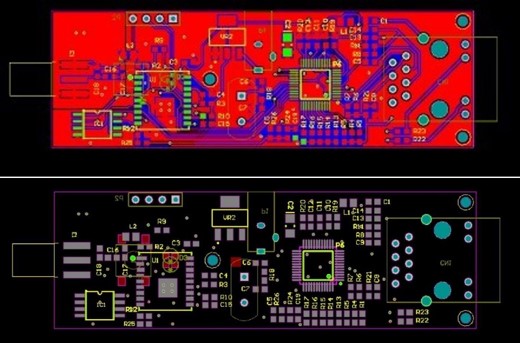

輔導流程

硬體規格優化

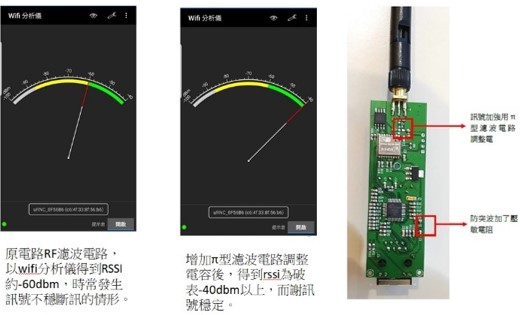

由小量智造服務團成員「岳僑漢企業有限公司 」進行PCB Layout設計製作,重新設計電路板,協助解決抗突波電路及修正Wifi傳輸穩定度,並優化網路通訊品質,進行可量產輔導實作。

輔導前

產品進案採用樂鑫ESP8266晶片,進行WiFi功能面之應用

輔導後

電路設計圖

電路防突波及WiFi通訊品質優化