Daudin Co., LTD. was founded with the goal of creating simpler, faster, and lower-cost tools and operating models for traditional industries that seek to undergo digital transformation. During this process, Daudin will also help enterprises to gradually implement smart industrial IoT solutions which feature digitization and visualization. In other words, Daudin's role is like a guide to walk industrial players through the journey of smart manufacturing in an efficient way. Daudin is a reliable partner as its parent company, Dinkle Enterprise, specializes in the manufacturing and development of precision terminal blocks for industrial use. With decades of experience in industrial manufacturing, it can provide customers with professional and stable-quality products with its independently-built, resilient supply chain.

Before its independent operation, Daudin belonged to a business department of the Dinkle Enterprise and had operated within the group for ten years. During this time, based on Dinkle's solid experience in industrial automation hardware manufacturing, Daudin developed a service model that integrates software and hardware construction in its solutions, making it a unique choice among other competing brands. Daudin's digital transformation solution not only includes a complete hardware structure and data analysis software, but also incorporates its accumulated experience regarding management and operation in its own digital transformation process. Such a comprehensive service scope has significantly accelerated digitization process for its clients and saved them a lot of trouble.

In Taiwan, traditional industries often encounter various kinds of obstacles during the process of digital transformation. In response, Mr. Wei, Project Manager of Daudin, summarized two most common problems facing enterprises from the company's experience of promoting AIoT in the market: 1) whether an enterprise has internal consensus and determination, and 2) whether exact operational needs can be clearly identified.

With digital transformation becoming a buzzword in recent years, companies may simply want to follow the trend, without a thorough evaluation of their own needs and the advantages/disadvantages of the company constitution. When the goals are unclear, it is difficult to verify the benefits of digital transformation, thereby deteriorating the confidence in further investments. Second, when an enterprise intends to carry out digital transformation, the first question is always how much resources should be invested, and at what levels should the enterprise make corresponding adjustments. When Taiwanese enterprises execute digital transformation, they tend to first "test" the introduction of digital transformation in certain aspects of manufacturing, or introduce it to only 1-2 of its production lines. If successful, the enterprise will then expand it to the entire production process. However, if decisions regarding digital transformation are not made by the management level, but commissioned to researchers or certain departments, problems such as cross-department communication, incoherent development/promotion, or inefficiency will often occur.

On the surface, digital transformation seems no more than updating equipment and deploying more sensors for data collection to improve data latency and reduce labor costs through automated data collection. However, to truly maximize the benefits of digital transformation, data processing/analysis should also be incorporated besides data collection, so that operational decisions could be made based on the data collected. That is, in addition to production management, the digital DNA should be embedded into the corporate structure through overall architecture planning in terms of equipment maintenance, raw material procurement, financial planning, etc. Sometimes, it is even necessary to redesign the workflow of each department in a digitization-oriented perspective.

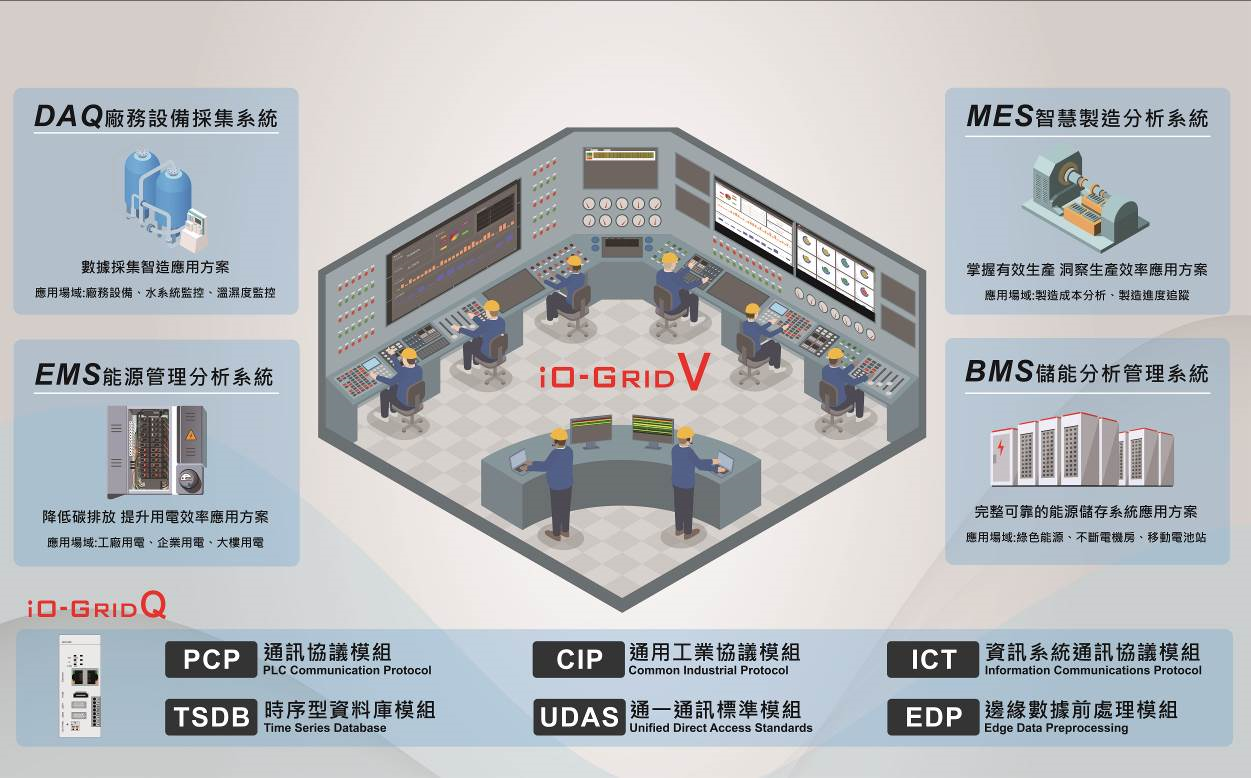

Through practical experience accumulated over the past decade and the manufacturing capabilities of its parent company, Daudin has cooperated with stakeholders in many different fields to help introduce AIoT and Industry 4.0 solutions. Different industries have their own manufacturing process architectures, professional domain knowledge, specific communication protocols, etc. Even companies in the same industry can have different needs. To solve this issue, Daudin has found the common denominator applicable to all industries, and has implemented their findings in automation-related software and hardware. Daudin's four major systems include:

DAQ Factory Equipment Data Acquisition System:

Collects real-time factory parameters and equipment statuses, such as each machine's current operating status, the process instructions being executed at the moment, equipment condition, real-time capacity of a production line, etc.

MES Smart Manufacturing Analysis System:

Analyzes and visualizes production and manufacturing management information, e.g., production line utilization rate, mass production target achievement rate, overall production capacity trend, etc. by presenting statistically processed data in charts to facilitate decision-making.

EMS Energy Management & Analysis System:

Collects and manages energy data, while compiling the maximum power consumption profile in a section as well as real-time power consumption profile consisting of energy consumption data, such as electricity, gas, water, or even carbon footprint, which can help enterprises implement policies related to net-zero carbon emissions in the future by offering all relevant information needed for carbon emissions inspections.

BMS Energy Storage Management & Analysis System:

Extends the service of the EMS system to energy storage demand and battery management, which can help factories achieve better power efficiency in energy management when they introduce their own power generation equipment in the future; in cases of grid demand response, the system can also help factories save costs on electricity.

A lot of system integration teams on the market specialize in software development. When planning projects, they are used to building on their MES and ERP development experience, and tend to look for ready-made hardware equipment on the market to form the hardware architecture. However, when the architecture needs to communicate with machine signals, sometimes problems that prevent smooth connection would occur. In this regard, Daudin's edge computing devices have powerful communication capabilities and built-in communication systems for various equipment such as PLCs, robotic arms, and CNCs from 40-50 brands on the market. The device is also equipped with RS-485, RS-232, and RS-422 communication sequences and Ethernet interfaces, which gives it a competitive edge because it can directly process raw data from various kinds of sensors.

Although Daudin has developed an all-in-one, cross-domain industrial automation smart software module, the company is still exploring production management expertise in various fields, and AI-driven data analytics has emerged as the top-tier gateway of choice. Besides investing in research by its own software development team, Daudin is also aspiring to become a data provider since it has become an expert in data collection, in order to develop a more fitting market position among the its many competitors in the area of AI analytics. Through the sharing of open data, Daudin expects to collaborate with more external teams and develop the best management models for different production lines.

Daudin Co., LTD. started out from the experience of terminal block hardware equipment manufacturing enable by its parent company, Dinkle Enterprise. Currently, it occupies a leading position in AIoT environment planning and deployment, data collection, among other core technical capabilities. The team's development direction is focused on business expansion at the moment. "Right now, we still need to educate our clients about the introduction of industrial IoT in Taiwan, and it takes time to communicate with various industries." After the IoT Service Hub garnered an in-depth understanding of several clients' needs, we introduced a number of manufacturers to Daudin after the matchmaking process. These manufacturers are from a wide variety of conventional industries like the food industry. All cases have now completed demand focus and entered the planning stage. In addition, Daudin has also launched its products on the ideas Hatch "III Hatch Market" platform, through which more users searching for solutions will be able to see the high-quality products of Daudin. With the help of the Institute for Information Industry (III) and the IoT Service Hub, Daudin will certainly be able to promote its solid high-tech solutions to various industries in a much more efficient manner.

>>Find the product(s) you need on the III Hatch Market: https://www.ideas-hatch.com/hatch_market_detail.jsp?id=554