Smart Modules Powered by Taiwanese IC Drive Innovation in Coffee Roasting, Tea Baking, & Microalgae Farming

So far, 2025 has witnessed the recovery of global economy since the pandemic, and is thus hailed as the "The First Year of AI Application at Scale." Under such trends and with accelerated implementation of various AI technologies and applications, experts believe that the semiconductor industry is about to enter a new era. In Taiwan, the semiconductor industry has long played a key role on the global arena, as it boasts advanced process technology and highly mature wafer foundry models. With a complete ecosystem and efficient supply chain, Taiwan's semiconductor industry provides high-performance solutions at low power consumption to support the computing performance and needs of diverse AI/IoT applications. Such a leading position has also driven companies from diverse backgrounds to invest in R&D and application innovation to seize market opportunities.

For more than a decade, the Institute for Information Industry (III) has been deeply engaged in the innovative application of IoT technology, and has, to date, launched more than 10 smart modules powered by Taiwanese IC based on wireless MCU technology. According to different requirements, such modules either integrate various sensor components, or even support edge computing. These modules have helped establish a niche in the innovative market, further integrating Taiwan's design and manufacturing capabilities, accelerating the implementation of smart solutions, and thereby boosting overall industry competitiveness.

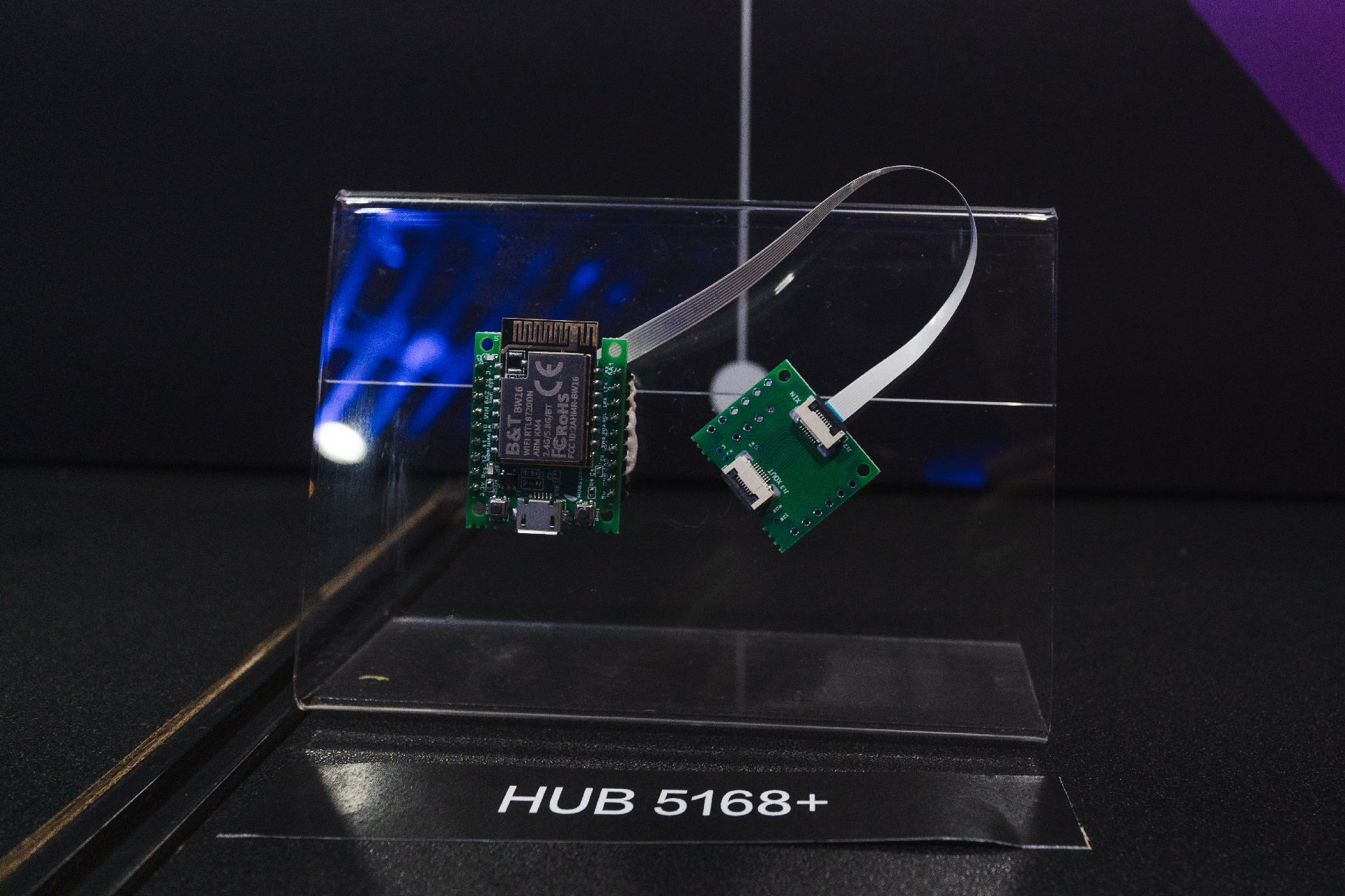

HUB 5168+, An Indispensable Wireless Solution for IoT Scenarios

Efficient and stable data transmission is key in all IoT devices, and it relies on the wireless communication technology chosen. Building on Realtek's RTL8720DN, the III launched its first smart module "HUB 5168+," which supports BLE 5.0 low-power Bluetooth and 2.4G/5G dual-band Wi-Fi transmission. The module is fully compatible with the Arduino Integrated Development Environment, and is thus highly scalable. With I/O expansion board, it can even become an OLED display module with I/O interface, helping IoT devices maximize their benefits in different scenarios.

In this regard, the III has established Taiwan's IC smart module standard framework and provided development tools, integrating cross-domain technologies to create innovative, cross-industry smart solutions. This approach not only preserves and shares professional expertise but also serves as a model for how technology can drive digital transformation across various fields. Below are some case studies for your reference.

1. Smart Coffee Roaster: Personalized Roasting Experience with Precision, Users Can Craft Flavors via Mobile App

For many people, coffee has become an essential part of daily life. Whether it's a morning pick-me-up or a relaxing afternoon break, coffee is deeply woven into everyday routines. As consumers' expectations for coffee quality continue to rise, many coffee lovers are no longer satisfied with just drinking it. Instead, they are delving into the coffee-making process, seeking a more immersive and personalized experience.

Recognizing such trends, If Then Else Limited developed the "not·a·cafe" smart coffee roaster. Designed for both home and commercial use, this roaster enables coffee enthusiasts to easily craft the perfect coffee beans and customize flavors to suit their preferences.

The team put great effort into optimizing the design, focusing on the heating tube and motor system. By achieving the perfect balance between efficiency and roasting capacity, they enhanced the equipment's overall performance while minimizing energy waste, which ensures that users can enjoy their coffee in a more sustainable way. A crucial aspect of the roasting process is how the coffee bean flavor evolves with changes in the "roast curve." The introduction of HUB 5168+, the smart module powered by Taiwanese IC, enables users to remotely and precisely control key roasting parameters through an app, including bean temperature, air temperature, and electric heating settings. This advanced control allows for fine adjustments, ensuring that every user can craft their ideal coffee beans to match their personal preferences.

Beyond hardware innovation, the team also developed the "not·a·cafe" digital platform, designed to build a vibrant coffee community. This platform integrates multiple functions, including purchasing, green bean trading, and roast curve sharing, creating a space for coffee enthusiasts to connect and collaborate. Users can share their roasting experiences on the platform, or exchange tips or different techniques. This interactive space not only makes the roasting process more enjoyable but also helps cultivate coffee culture and offers opportunities for more consumers to explore and practice the art of roasting.

2. Digital Transformation & Smart Charcoal Tea Baking

Charcoal tea baking is a skill that requires exquisite techniques. Its unique taste and rich flavor cannot be replicated by electric roasting, making it a truly distinctive process. Throughout the process, the tea maker must carefully monitor the charcoal fire and the furnace temperature, adjusting the roasting time and heat levels based on the specific characteristics of each batch of tea leaves. In addition, they must skillfully turn the leaves in the roasting cage and use their hands to sense changes in texture, ensuring even heating and a consistently rich flavor. It is easy to see that this technique is the result of years of accumulated experience and mastery.

In traditional industries, passing down expertise is essential. However, as these industries grapple with labor shortages, T.C.D. COMMERCIAL has also realized that the younger generation is becoming less interested in learning the art of tea-making. To address this challenge, the III stepped in and leveraged technology to support the traditional charcoal tea baking process. With HUB 5168+, we developed an advanced temperature control system for charcoal baking. Equipped with sensors inside the tea baking furnace, this system monitors the surface temperature of the tea leaves in real time and allows for remote control. This innovation significantly reduces the manual workload for tea makers, making the process much more efficient. At the same time, by analyzing data on how ambient temperature affects the baking process, traditional charcoal tea baking can be enhanced with scientific methods, paving the way for a more precise and innovative approach to tea crafting.

To this day, T.C.D. COMMERCIAL has been deeply rooted in the tea industry for over 60 years, consistently upholding a spirit of innovation throughout its history. In the era of IoT, the digital transformation of tea baking technology will bring fresh vitality to the tea industry, driving continuous industrial upgrading and development.

3. Smart Microalgae Farming & Real-Time Monitoring of Carbon Capture Data

Ocean Star Bio-Tech is a leader in aquatic seedlings and low-carbon aquaculture, actively pursuing energy conservation and carbon reduction. Drawing on its extensive experience in marine biological breeding, the company has successfully developed innovative products that integrate carbon management with IoT technology. For example, the M-Map air purifier is a device that uses microalgae to clean the air. Combining advanced IoT technology with remote control via app, it offers multiple functions, including oxygen production, air purification, odor removal, and the generation of natural negative ions. The core technology of the M-Map air purifier relies on its built-in IoT functions, featuring the HUB 5168+ wireless module to enable real-time data transmission and remote monitoring. The device can automatically collect data on the growth status of microalgae and carbon capture, storing and analyzing it through a cloud platform. Users can view real-time data directly on the mobile app and access detailed reports on microalgae maintenance and carbon capture benefits. This enhances the user experience and ensures transparency and accuracy in the carbon management process. The M-Map air purifier is equipped with various environmental monitoring technologies that track the real-time changes of microalgae in different environments, optimizing its carbon capture efficiency. The remote control feature allows users to adjust the operating mode at any time, enabling them to optimize the equipment's performance based on specific needs.

As part of its long-term operational plan, the team introduced a feedback system to encourage more consumers to adopt micro carbon reduction devices. The system tracks carbon reduction data and converts it into shopping credits, offering discounts at partnering stores. This seamlessly integrates advanced technology into everyday life, ensuring that carbon reduction benefits and low-carbon education move beyond theory and are actively implemented in real-world situations.

From the innovative design of the smart coffee roaster to the preservation of traditional tea baking techniques, and the green application of microalgae carbon fixation technology, the digital visualization of all these key skills is made possible through Taiwan's all-in-one tech support platform, the IoT Service Hub. At the IoT Service Hub, we have developed a "black box" to kickstart the digital transformation of the industry. By using locally-manufactured smart module as reference design, we integrate the full range of supply chain resources—spanning circuit and mechanism design, mechatronics, trial production, and service testing in order to accelerate the development of innovative services and foster synergy across various industries.