T.C.D. COMMERCIAL (Teagraphy) Joins Hands with Teamosa and Uses IoT for Charcoal-Baked Tea Making

As traditional industries develop and grow, different business operators will have different opinions on the advancement of technology and changes in concept. Some begin to invest in more efficient production, while others may stick to their long-standing practices. Many factors may influence such choices, and different approaches all have their own supporters. Among them, T.C.D. COMMERCIAL chose the latter with their tea making business, and still uses the ancient "charcoal baking" method to bake tea leaves. At present, less than 10% of Taiwanese tea makers still adopt this traditional method.

Founded in the 1970s, T.C.D. COMMERCIAL was mainly engaged in agriculture and animal husbandry in the early days. The founder used the company's land for raising pigs and growing tea. However, few people know that the company in fact entered the tea making industry by chance. Back then, because tea manufacturers could take the initiative and make bargains regarding price, there was high uncertainty for tea farmers. In order to avoid such issue and prevent raw materials from being wasted, the company decided to purchase tea-making equipment and learn how to make tea. After the family's third generation took over the business, they decided to work on brand development and launched multiple tea brands, such as Teagraphy and Tan Cha Dau.

Charcoal baking mainly uses the far-infrared heat generated by burning charcoal to block the caffeine and theophylline in the tea leaves. It requires a long time and slow fire at steady temperature to drive away the unfavorable smell and taste in the tea leaves. According to Mr. Teng, the third-generation owner of T.C.D. COMMERCIAL, "The main purpose of baking is to reduce the water content, remove impurities and the unfavorable smell, and also to extend the storage life of tea. It can also bring out a special taste and unique aroma." Through roasting and baking, the storage life of tea can be extended; the flavor differences created during the process can also cater to the consumers' different needs in taste.

In the early days when there was no electricity, tea could only be baked using charcoal. However, evolving with the times, the tea making industry has also ushered in technological updates. Electrical equipment such as electric box roasters, electric roasting cages, and non-fire charcoal bakers have brought convenience in operation and has become widely adopted by the industry. In this sense, tea baking can also be achieved using electrical equipment to roast more tea leaves at the same time and also to precisely control the temperature and time.

However, the unique taste and flavor of charcoal-baked tea can never be replicated by the process of electric roasting, and charcoal baking also requires more sophisticated skills to operate. For example, the tea maker needs to stand by at all times, and flexibly control the roasting time and temperature according to this particular batch of tea leaves. The tea maker also has to turn the leaves in the cage from time to time to ensure a uniform flavor.

Each roasting cage can hold about 6 kg of tea leaves, and it takes 6-10 hours of non-stop roasting to complete the process. Just using longan charcoal to heat the oven and adjusting the temperature can be quite challenging. During the process, it is also necessary to constantly observe the condition of the fire and the temperature. Tea makers will also feel the tea leaves with hands and turn the leaves in different parts of the cage to make them evenly heated. Thus, this kind of work requires a lot of practice and experience. What's more, 30 kg of longan charcoal is required for each oven session, which can last for 5-6 days and provide the temperature required for tea baking. In other words, tea makers need to endure long working hours and pay constant attention to the temperature and the condition of tea leaves. It's not hard to imagine how tiring the roasting process can be. Like other traditional industries, given the overall shortage of human resources, it is increasingly difficult for the tea industry to find new blood to learn the tea making practice.

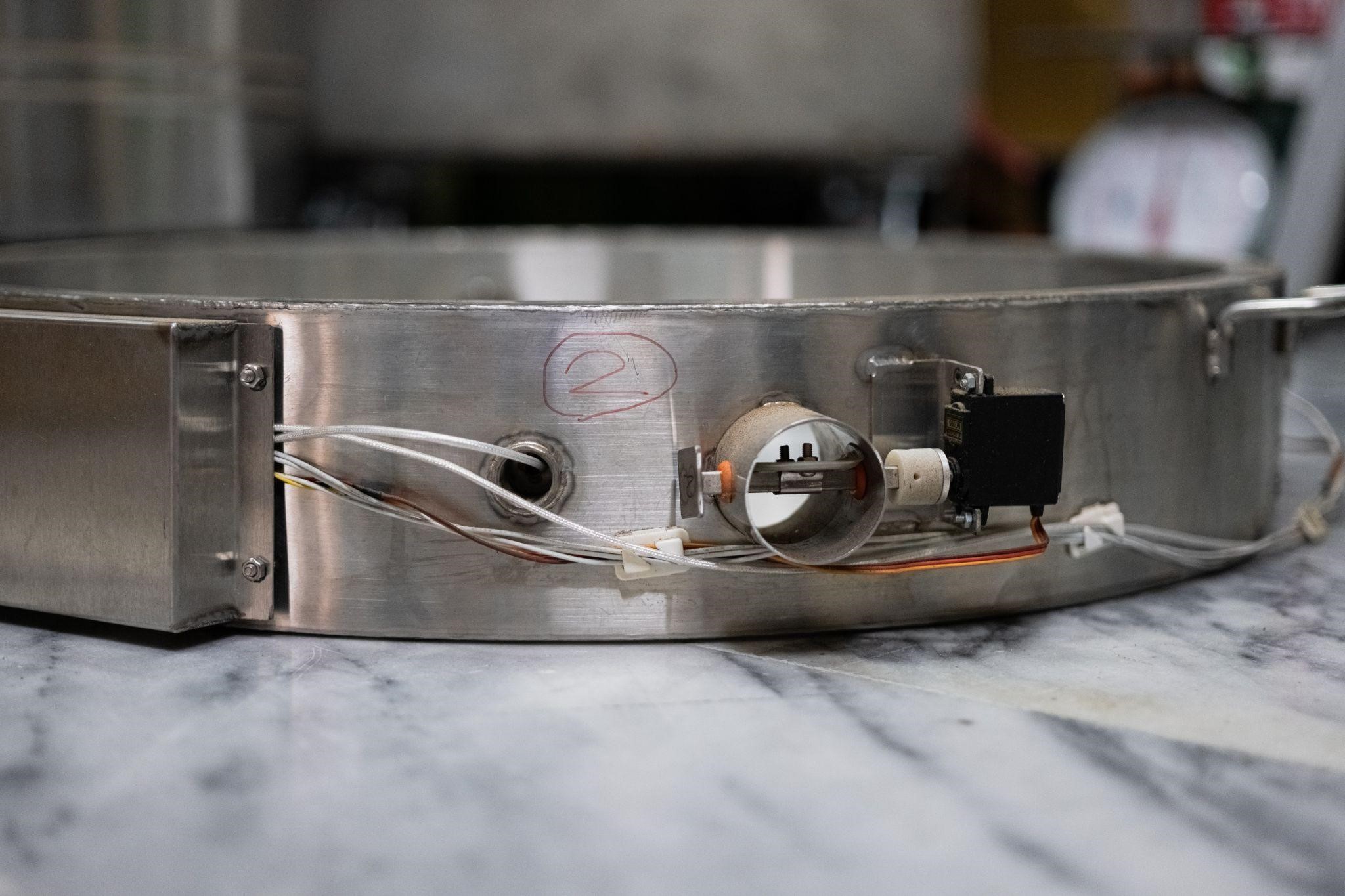

Nevertheless, such crisis is also a turning point. Such a one-person operation also stimulated Teng to think about how he could improve the traditional charcoal baking process. The most intuitive idea he had was to use a sensor to measure the temperature in the oven and remotely control the temperature so that tea makers can get enough rest. After coming up with the idea, he worked with Teamosa to modify the tea roaster by raising its height and installing air valves in the four diagonal holes. Then, the roaster was connected with an automatic control device to control the opening/closing of the valves to achieve temperature control. "For example, I can set the temperature at 110°C; if the temperature in the oven reaches the target, the valves will open to allow hot air to escape and thus cool down the oven, or I can manually open or close the valves at any time through the app to control the oven temperature," Teng explains. The seemingly simple temperature control equipment turns out to be a key device when making charcoal-baked tea. What's more, the device can also allow tea roasters to allocate human resources more effectively.

Currently, T.C.D. COMMERCIAL is working further with Teamosa to develop the second-generation tea-baking assistive system, which uses domestic IC to make the entire equipment wireless in a simpler design, using only one temperature sensor (as compared to four in the first generation) to detect the temperature at multiple points in the oven. In addition to becoming wireless, the matching app also takes advantage of IoT to collect data during each roasting process, such as oven temperature, tea leaf surface temperature, or even whether ambient temperature had an influence on the end product. With the data recorded and analyzed, scientific methods can well bolster the traditional charcoal baking method and create a new era for tea making.

When talking about the company's partnership with Teamosa, Teng said that the resources of III's IoT Service Hub were crucial in allowing him to realize the equipment that he had only imagined in his mind since he knows very little about the technology involved. In addition to the initial technical support from Teamosa secured via the matchmaking service by the IoT Service Hub, the project manager of the Hub also helped the two parties communicate, so that they could continue to work together and identify the functions required for the tea-baking temperature control system, and further analyzed the technical requirements with the dev team. During the process, the project manager was really a critical supporting role. "Without the assistance of the Hub, we wouldn't have been able to complete everything so quickly," Teng says as he looks back on the development process.

From pig husbandry to growing tea, then purchasing their own equipment to make tea, and even establishing tea brands in response to e-commerce and trying to change consumers' tea-drinking habits, T.C.D. COMMERCIAL has never stopped their innovation for more than six decades. Now, with the introduction of IoT in their tea-baking equipment, they will surely continue to develop and sprout new leaves in the future.