Shared Practical Development Skills via Actual Cases at "Maker Community Forum"

To introduce the applications of a variety of domestic ICs for IoT devices, the Institute for Information Industry (III) organized the " Maker Community Forum" at the IoT Service Hub Annual Conference, and invited many active members in the maker community to share their extensive development experience in keynote speeches. From the presentations, the audience was able to gain valuable experience in the concept development IoT devices, as well as practical technical solutions that may come in handy during the development process.

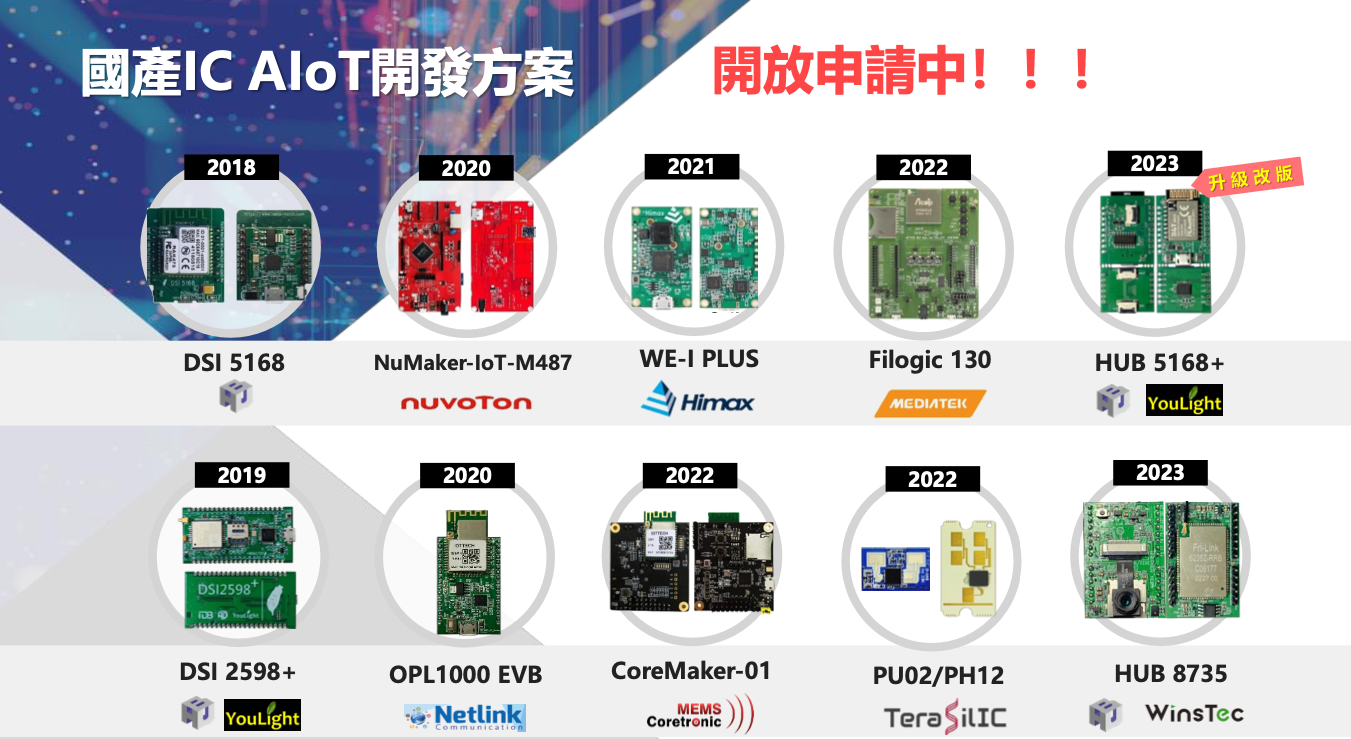

To begin the forum, the III team first introduced how the IoT Service Hub has been promoting cooperation between the domestic IC support and the application to achieve synergistic effects. So far, the IoT Service Hub has established three branches in northern, central, and southern Taiwan to improve service penetration and density. With the three major mechanisms of 1) domestic IC smart manufacturing promotion, 2) smart manufacturing acceleration for products, and 3) industrial transformation through smart manufacturing, the IoT Service Hub seeks to create a modular solution from IC design to IoT product development guidance, by means of providing technical resource matching, enterprise demand matching, brand marketing, etc. in a complete service chain, its aim being to foster solid partnerships and accumulate domestic resources in the maker community and to create a reciprocal IoT ecosystem in the private sector.

In terms of promoting domestic IC smart manufacturing, experts from the academia and key players from the industry are called on to organize domestic IC service groups to carry out IoT development design, teaching plan design, and case implementation for selected domestic ICs, thereby promoting their introduction and application in market-proven products and solutions. For Taiwanese companies intending to invest in the IC/module design and development of the innovative AIoT market, the IoT Service Hub can offer open-source data and matchmaking services to ensure interdisciplinary resources, with the ultimate goal being to promote open-source domestic IC technology and commercially successful AIoT applications.

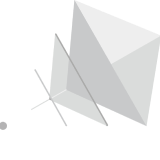

For example, the "earthquake alarm" made by Yishifu (益師傅) using the HUB 5168+ EVB is a perfect solution that caters to the needs of the Taiwanese people, since earthquakes occur frequently in the country. In his presentation, Yishifu first introduced the working principles of common earthquake alarms on the market, and then explained why he chose HUB 5168+ for development purposes. Since HUB 5168+ has the feature of stackable modules, it is convenient to add communication modules and sensors with different functions. Also, lithium polymer batteries can also be connected in series directly through the power expansion module. In terms of function design, the earthquake alarm has the basic function of detecting the intensity of earthquakes. In addition, it can also detect on-site brightness through the DH1750 light sensor to actively turn on the 3W LED to provide lighting if necessary.

At the same time, it is equipped with an electromechanical natural gas valve switch with RF function, which can cut off gas supply when an earthquake occurs, helping to avoid further hazards. What is more, the gadget can also send alert messages to the default chatroom via "LINE Notify" (a notification service from LINE, a communication software)

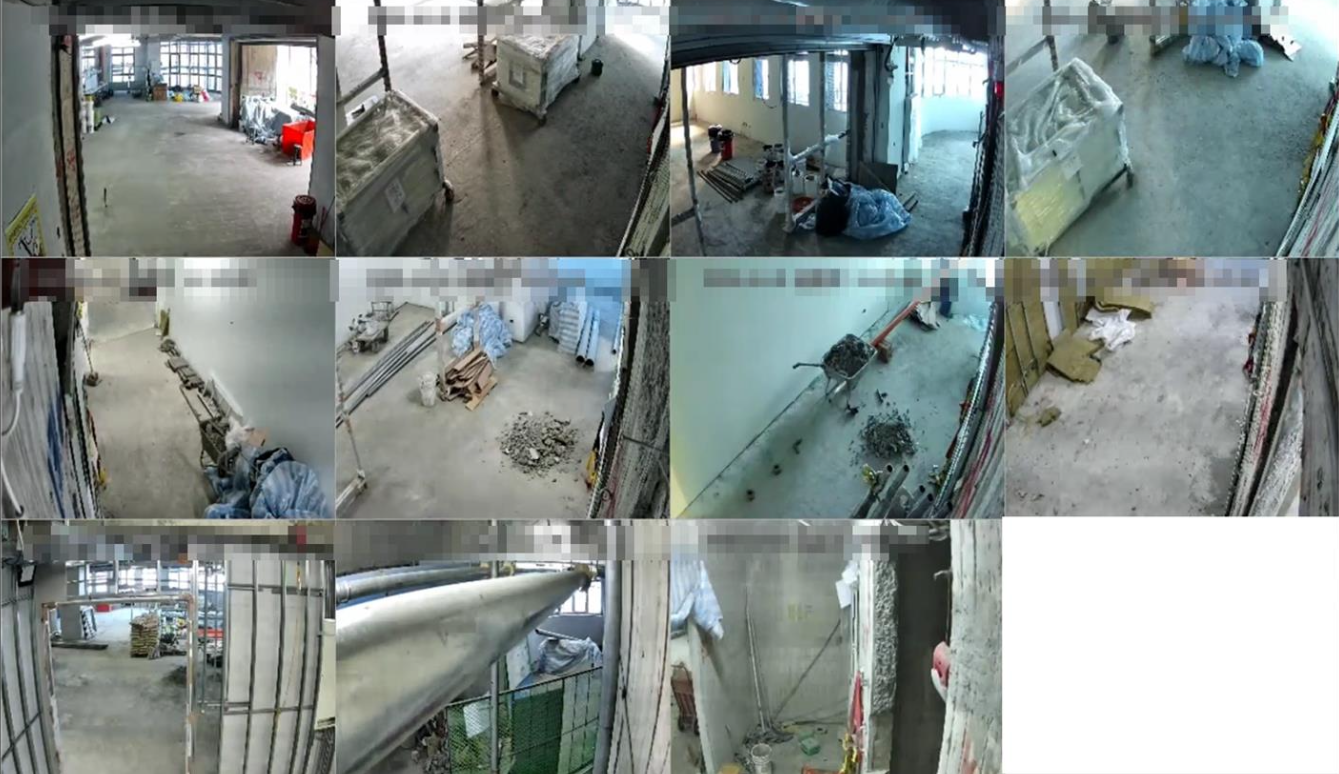

In another presentation, Professor You, nicknamed the Night Market Maker by the community, shared how the AMB82 mini EVB is used in the field of industrial security. AMB82 mini has a 5megapixel super-wide-angle lens. In addition to basic communication functions, it has built-in audio and video decoders and supports multiple streaming formats. Thus, it has complete audio/video functions with a built-in neural network, making it even capable of edge computing. Taking advantage of the EVB's superior features in image processing, Professor You used AMB82 mini in the case of construction site safety management.

To start with, the built-in face recognition function of AMB82 mini is used to create a portrait database for construction workers, which can automatically identify whether a staff member has authorized access for the area. If anyone without authorization enters, a notification can be sent to the management staff after connecting the solution to LINE (a communication software). In addition, another built-in function was also used to train with the YOLO model, so that the program can monitor whether any construction worker is not wearing their safety helmet from on-site images, thereby achieving safety management purposes. In this case study, the speaker explained the details of how to train the YOLO model and connect MQTT images to serve as synchronization monitors. The tips from the presentation greatly benefited participants of the workshop.

Next, Kevin Chen from Kevin's Lab shared the development potential of HUB 8735. This EVB has multi-functional image processing capabilities, supports the Arduino native development environment, and has a built-in NPU AI engine to accelerate the processing of AI models. With the features above, HUB 8735 is one of the few AIoT modules with a camera and AI computing capabilities at the same time, which makes it a good choice in image recognition contexts. In terms of vehicle control, the L9110S motor driver module is used, and the motor can drive dual motors at the same time. For the control interface, V7RC developed by V7 Idea Technology Ltd. was introduced, which allows users to control vehicle dynamics on a mobile phone through Bluetooth and Wi-Fi. In this case, although the subject was a mere small remote control vehicle, the solution actually demonstrated great value on special occasions when paired with image recognition functions, such as hazardous environment survey, disaster relief, etc.

Finally, the last speaker Mr. Chang showcased the possibilities of domestic EVBs in industrial applications. Like the previous speaker, he chose HUB 8735 out of its outstanding performance in image recognition. Mr. Chang used the case of metal parts detection to introduce the details of how to implement image recognition and its AI model training. First, after completing basic settings, Arduino IDE is used to operate the Smart CAM. The feature is then burned into HUB 8735, and then connected to VLC Media Player. Next, users can use labelIMG (graphical image annotation tool) with Google Colab to create a model. The data is pre-processed and then enhanced through YOLO. After training, it is burned into the chip, and there, the training of your own model is completed!

From all the shares cases at the workshop, we can observe that although the speakers chose different domestic IC EVBs, the same selection logic applies. That is, users would think about how the functions of different EVBs can meet their needs after careful analysis. At the same time, we can also learn that AI-related functions will be more inseparable from IoT devices in the future. The content shared by all speakers not only addressed key development skills for makers, but also brought new innovative stimulation and inspiration to the maker community.